A pyrolysis plant is a valuable machine for waste recycling. Apart from the cost of the fuel, it also saves fundamental costs, such as electricity, water, area, and labor. However, the cost of a pyrolysis plant differs from one country to another. Hence, it is important to discuss business plans with a professional sales consultant. Here are some important factors that will help you determine the cost of a pyrolysis plant:

Price Of Pyrolysis Equipment

The pyrolysis plant cost is directly related to the amount of funding that an investor has available for the project. This is an important consideration for the investment, and an investor should carefully plan their budget before purchasing the plant. It is recommended to find a manufacturer who has experience in the field, as they can customize a project plan that meets the requirements of the customer. If an investor does not have the budget to spend on a large scale project, a smaller batch model is also an affordable option.

Size of Pyrolysis Reactor

The cost of building a pyrolysis plant varies depending on its design and feedstock rate. Larger-scale plant systems are usually cheaper, although large-scale conversion has not reached commercial status. For instance, researchers from the University of New Hampshire studied the cost of producing bio-oil from wood chips as a #2 fuel oil substitute. In their study, they used a fast pyrolysis reactor with feedstock rates of 100, 200, and 400 tons per day.

Pyrolysis Plant Cost

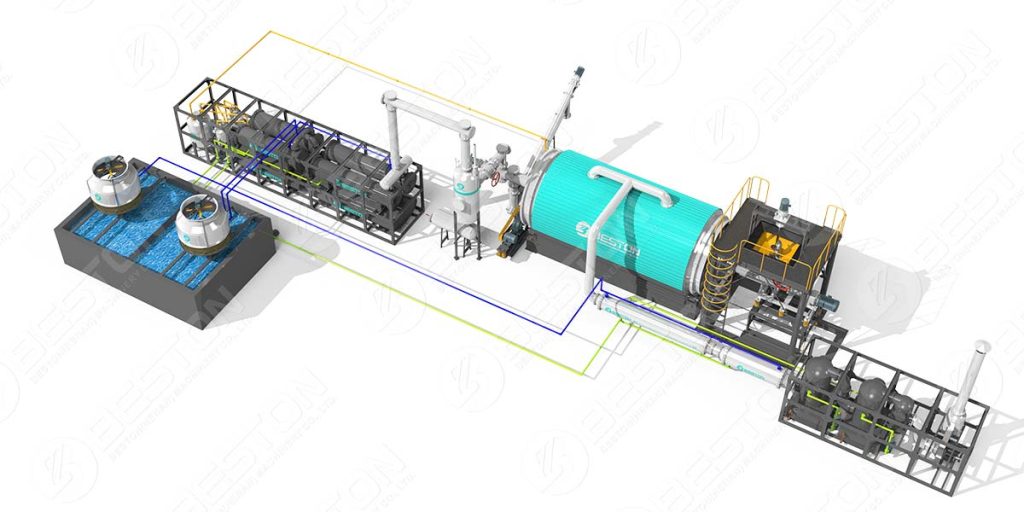

Design

Design of pyrolysis plant for sale cost can be high, depending on the size of the facility and the materials to be processed. The yield of a pyrolysis plant can range between thirty and forty percent of radial tyres. For smaller sizes, yields are in the range of thirty to forty-four percent. The cost of a pyrolysis plant can be considerably lower than the cost of producing oil from industrial fossil fuels.

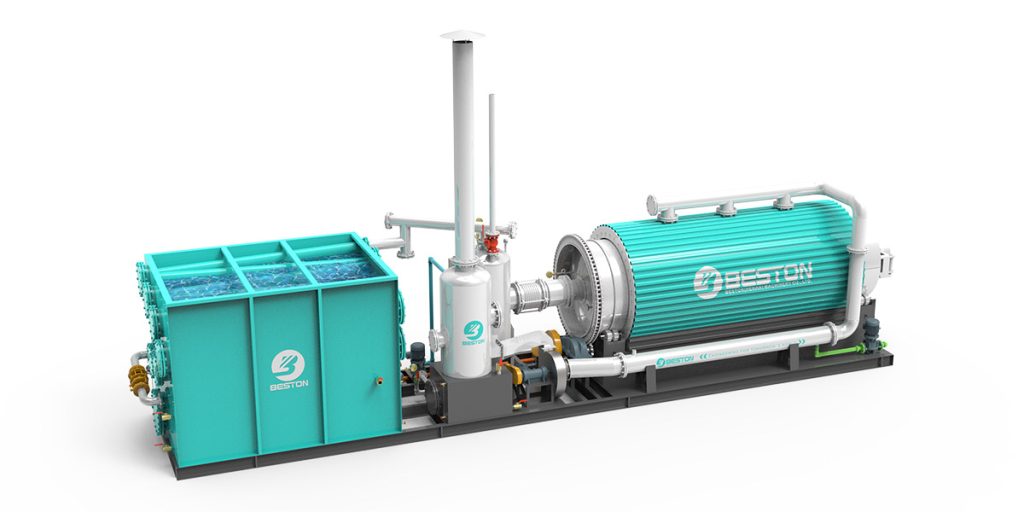

Automation

Generally, the automation of pyrolysis plant cost depends on the amount of capital an investor is willing to spend. A fully automated plant runs round the clock and costs a significant amount of money. Apart from the initial outlay, the owner of such a plant has to bear costs for the processing of raw materials and storage of the finished product. But, as automation is a necessary part of the operation, the price is justified by its efficiency.

Quality of Materials Used in Pyrolysis Equipment

Pyrolysis is a process in which fuel is converted into a form that is suitable for transportation. Many fuel suppliers use low-quality components that are not designed for high-volume production. For example, many of the heat exchangers, fuel pumps, and pipes used in pyrolysis plants are not made from stainless steel. This is a problem because the pyrolysis oil is extremely corrosive. Another problem is the quality of the exhaust fans, which are required to convey the pyrolysis exhaust gases through scrubbers to the exhaust pipe. Most exhaust fans used in pyrolysis plants are made of plain carbon steel, and the condensate from the exhaust gas is highly acidic. More information on Beston Group here.

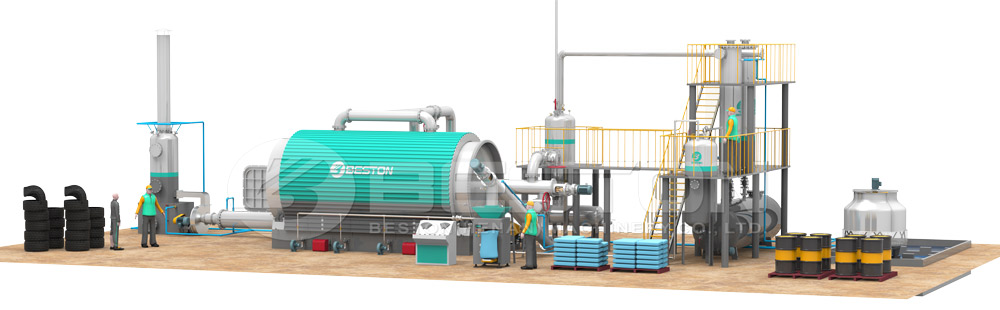

Layout of BLJ-16 Pyrolysis Plant

Return On Investment

The ROI of a waste tyre pyrolysis plant can be astounding. It is possible to get your money back within a few years of starting your own plant. A sample ROI calculation is shown below, which highlights the economic benefits for the country and the environment. Apart from this, pyrolysis is highly viable and cost effective in terms of technique. Moreover, there are ready buyers for pyrolysis-derived products.