With a bamboo charcoal making machine, you’ll easily be able to convert bamboo into charcoal. If you have access to bamboo that would ordinarily be going to waste, a machine like this could be a sound investment. Of course, it’s important to seek out the best bamboo charcoal machine available to you.

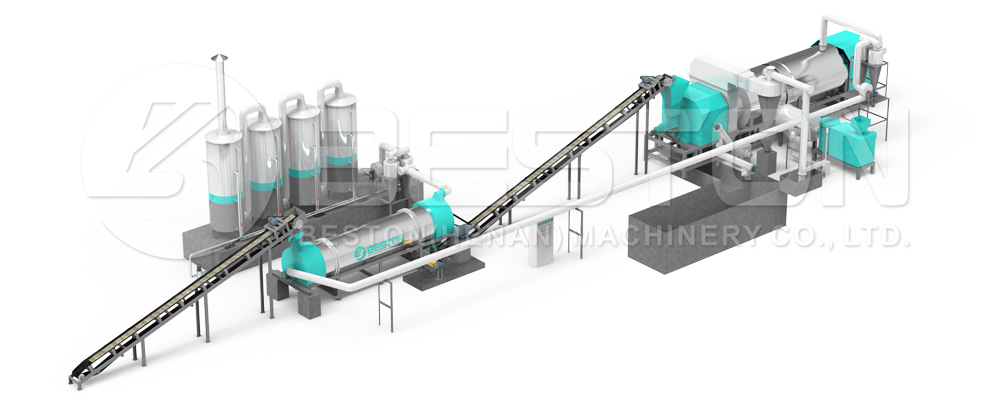

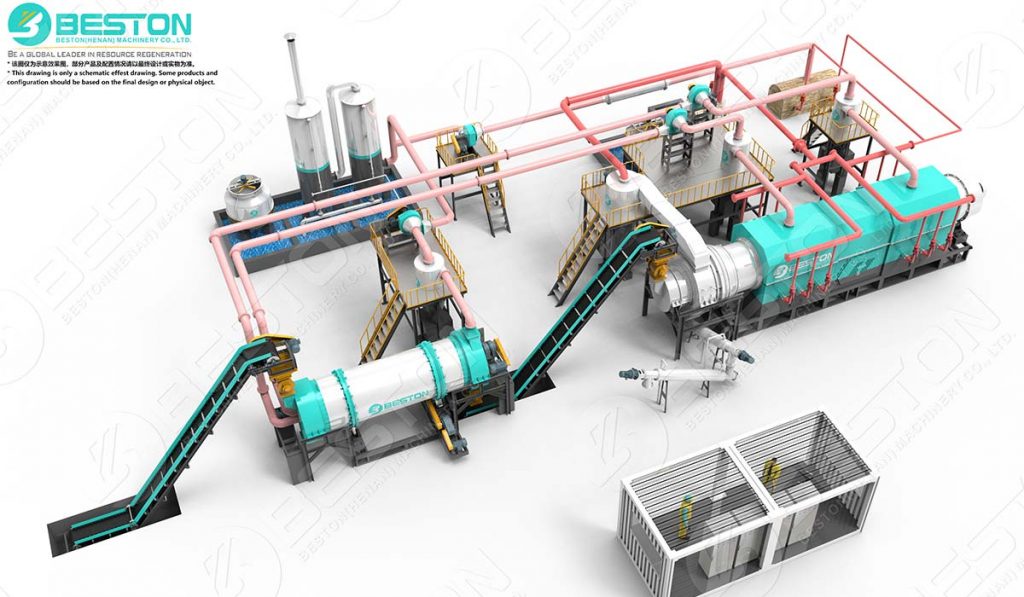

Bamboo Charcoal Making Machine

Have a Budget In Mind

How much will you have to pay for your charcoal making machine? The cost of biochar equipment can vary greatly based on the model you buy and the vendor that you work with. It’s not unusual to see price differences of thousands of dollars or more. That’s why it’s wise to consider what you’re comfortable spending before you start seriously looking at your options.

The budget that you set should be a reasonable one. If you simply focus on finding the cheapest equipment available, you may wind up purchasing a palm kernel shell charcoal machine model that’s prone to problems. Set a realistic budget and utilize price filters so that you can focus on options that fall within that price range.

Find a Machine That Goes Beyond What You Need

While it’s important to confirm that the equipment you buy is capable of meeting your production needs, you won’t want to buy machinery that you’ll be pushing to its limits. Instead, you’ll want to look for equipment that offers more than what you need.

Why pay for more than you need? In many cases, there won’t be a significant price different between a model that barely meets your needs and a model that can do all that and more that. If you choose a machine that can handle more than you need to do, you’ll be putting less strain on the machine, which will reduce its lifespan.

Work With a Supplier That You Can Depend On

You’ll find that it’s far easier to select a model that delivers what you need if you buy from the right supplier. When you partner with a dependable seller, you’ll be able to choose from a range of high-quality products. You’ll also be able to ask plenty of questions and find out more about all of the choices that you have.

When you’re considering various sawdust charcoal machine suppliers, you should keep in mind that you don’t necessarily need to stick with domestic sellers. There are sellers in many regions that ship to buyers across the globe. Working with a supplier in a different region will give you more options, and in many cases, it will help you to save.

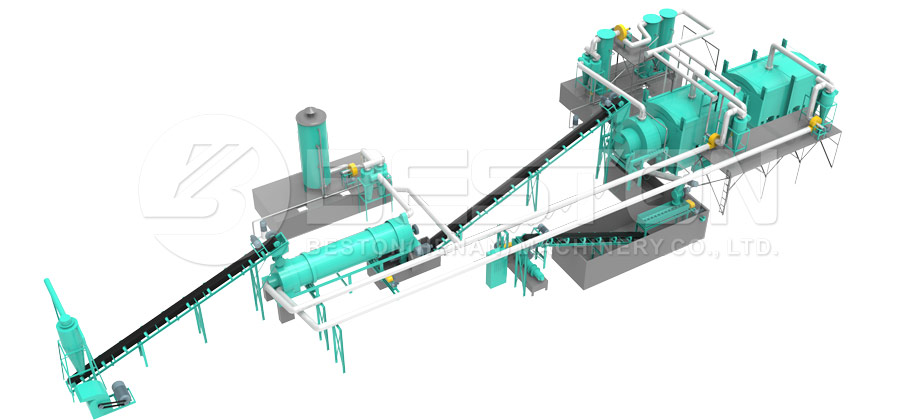

BST-30 In Spain

Compare Several Different Models

Since a bamboo charcoal making machine is likely to be a fairly significant purchase, you won’t want to rush to select a model. Instead, you’ll want to work to identify a range of suitable options.

Once you’ve found several options that seem like they could be suitable for your needs, you should compare these different models against each other. Look at the benefits and the drawbacks of each model, and make sure you’re considering all the costs. This will allow you to choose a model you know is right for you. Get high quality rice husk carbonizer here.