The demand for sustainable and eco-friendly packaging solutions is on the rise, and one promising avenue is the egg tray business. Egg trays, made from recycled paper, not only offer a cost-effective solution for packaging eggs but also contribute to environmental conservation. If you’re considering entering the egg tray business, this comprehensive guide will walk you through the steps to start your venture successfully.

Step 1: Research and Planning

Before you jump into the egg tray business, conduct thorough research. Understand the market demand, competition, and potential customers. Determine the types of egg trays in demand, such as 30-cell, 20-cell, or specialized designs for duck eggs. Create a solid business plan outlining your goals, target market, pricing strategy, and marketing approach.

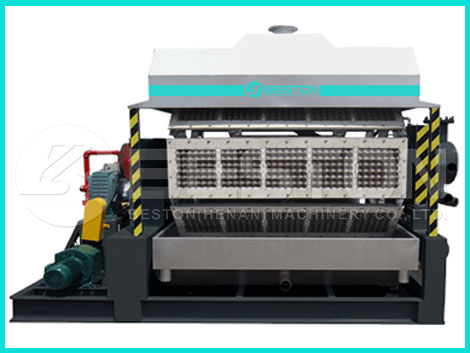

Step 2: Obtain Egg Tray Machine

The heart of your egg tray business is the egg tray making machine. These machines are designed to convert waste paper into molded trays. There are various types of machines available, including manual, semi-automatic, and fully automatic models. Choose a machine that suits your production capacity and budget. Consider factors like automation level, output capacity, and energy efficiency.

Step 3: Secure Raw Materials

To produce egg trays, you’ll need a steady supply of raw materials, primarily waste paper. Collect newspapers, magazines, cardboard, and other paper waste from local sources. Ensure the collected materials are clean and free from contaminants. Proper raw material management is crucial for the quality of your egg trays.

Step 4: Set Up the Production Area

Design a production area that accommodates the egg tray machine, raw material storage, and finished product storage. Ensure adequate space for the machine’s operation and maintenance. Create a safe and efficient workflow to optimize production.

Step 5: Install and Test the Machine

Once you have your egg box making machine, install it according to the manufacturer’s guidelines. Test the machine thoroughly to ensure it’s functioning correctly. Familiarize yourself with the machine’s operation, maintenance, and troubleshooting procedures.

Step 6: Develop Egg Tray Designs

Experiment with different egg tray designs to cater to various customer preferences. Your designs should offer adequate protection to eggs during storage and transportation. Consider customization options like branding or labeling to attract potential clients.

Step 7: Obtain Necessary Permits and Licenses

Check with local authorities to determine the permits and licenses required to operate your egg tray business. These may include business licenses, environmental permits, and health and safety certifications.

Step 8: Hire and Train Staff

Depending on the scale of your operation, you may need to hire staff to assist in production, maintenance, and administration. Provide comprehensive training on pulp molding machinery operation, safety protocols, and quality control measures.

Step 9: Production and Quality Control

Start the production process, focusing on maintaining consistent product quality. Implement quality control checks at various stages to ensure that your egg trays meet industry standards.

Step 10: Marketing and Distribution

Create a marketing strategy to promote your egg trays. Highlight their eco-friendly nature, durability, and cost-effectiveness. Establish partnerships with local egg producers, grocery stores, and markets for distribution.

You can contact Beston Group for a detailed project report about the egg tray machine.