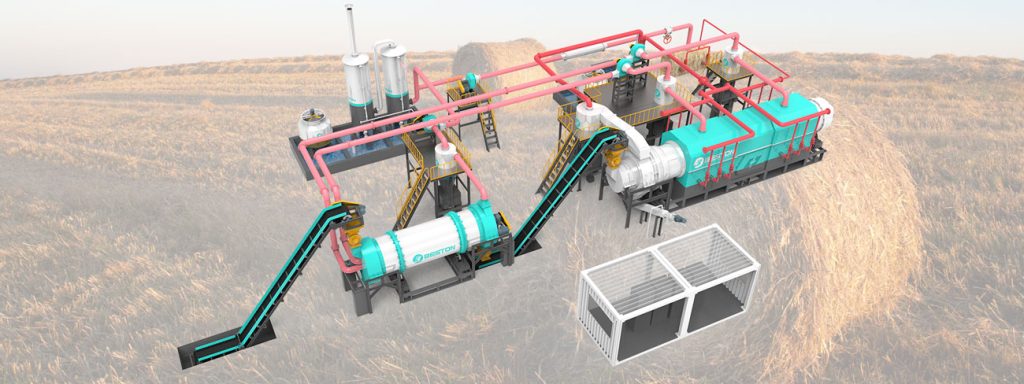

The Beston charcoal production machine is a versatile piece of equipment that is designed to process a wide range of biomass materials. This flexibility in raw material compatibility is a significant advantage for businesses involved in biomass recycling and charcoal production.

What Does This Raw Material Suitability Mean?

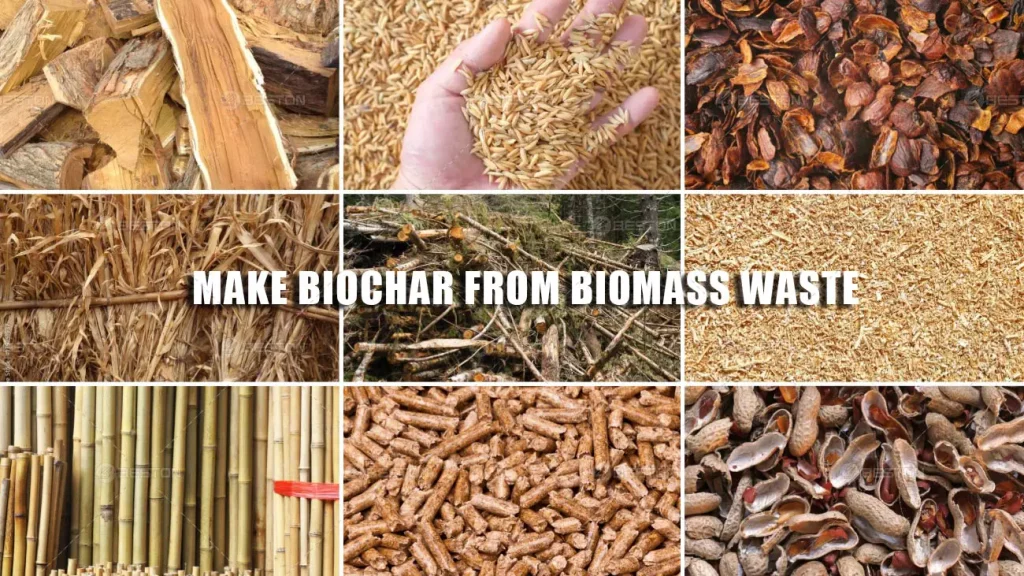

The ability of the Beston charcoal making machine to handle various biomass materials means that it can be used in diverse applications, providing businesses with more opportunities to convert different types of waste into valuable charcoal. This adaptability is particularly beneficial for regions where different types of biomass are abundant, allowing for more efficient and sustainable waste management practices. For instance, the machine can process materials such as:

- Wood Chips

- Sawdust

- Rice Husks

- Sugarcane Bagasse

- Peanut Shells

- Palm Kernel Shells

This versatility means that businesses are not limited to a single type of biomass feedstock, which can fluctuate in availability and cost. Instead, they can switch between different biomass materials based on what is most readily available or cost-effective at any given time. This flexibility helps in maximizing the efficiency and profitability of the biochar production units.

Why Do All These Biomass Materials Have the Same Suitability?

The primary reason all these different biomass materials can be processed by the Beston charcoal production machine is their similar composition, primarily consisting of cellulose, hemicellulose, and lignin. These three components are the building blocks of most plant-based biomass materials and they undergo similar thermal degradation processes during pyrolysis, which is the method used by the Beston wood/coconut shell/rice husk/straw/bamboo/sawdust charcoal machine to convert biomass into charcoal.

Cellulose

Cellulose is a complex carbohydrate that forms the primary structure of plant cell walls. It is a significant component of all biomass materials and is responsible for their rigidity. During pyrolysis, cellulose breaks down into smaller molecules, releasing volatile gases and leaving behind a carbon-rich solid residue – charcoal.

Hemicellulose

Hemicellulose is another major carbohydrate found in plant biomass. It has a more amorphous structure compared to cellulose and decomposes at a lower temperature during pyrolysis. The breakdown of hemicellulose contributes to the release of additional gases and the formation of bio-oil, further enriching the carbon content of the resulting charcoal.

Lignin

Lignin is a complex organic polymer that binds cellulose fibers together, providing additional strength and rigidity to plants. It is highly resistant to decomposition, which makes it an ideal precursor for charcoal production. During pyrolysis, lignin decomposes more slowly than cellulose and hemicellulose, producing a higher yield of solid carbon residue.

The presence of cellulose, hemicellulose, and lignin in all biomass materials means that they can all undergo similar pyrolysis processes to produce charcoal. The Beston charcoal production machine is designed to optimize this process, ensuring efficient conversion of various biomass feedstocks into high-quality charcoal.

Conclusion

In summary, the Beston wood/coconut shell/rice husk/straw/bamboo charcoal making machine‘s ability to process a wide range of biomass materials makes it an incredibly versatile and valuable piece of equipment for any business involved in biomass recycling. The common composition of cellulose, hemicellulose, and lignin in these materials ensures that they can be effectively converted into charcoal using the same pyrolysis technology. This adaptability not only enhances the efficiency and profitability of the charcoal production process but also supports sustainable waste management practices by providing a solution for diverse biomass waste.

By investing in a Beston charcoal production machine, businesses can take advantage of the abundant biomass resources available in their region, transforming waste into a valuable product and contributing to a more sustainable and circular economy.