A charcoal making machine is a unique device that utilizes the power of pyrolysis. It is a process by which materials are chemically changed, converted into different byproducts. The conversion of plastic, or even organic materials, using this process can lead to liquid fuel. It can also develop charcoal deposits. The charcoal can be extracted and sold, and subsequently burned, using this unique recycling process. To take advantage of the best carbonization process in the world, using a charcoal making machine(máquina para hacer carbón vegetal), Beston is the company you should trust.

How The Pyrolysis Process Works

This process is designed to do a couple different things. First of all, it can take material such as coconut shells, plastic, sawdust, or even organic sludge and convert it into several different materials. This will include charcoal, biofuel, and can even produce bio oil for different purposes. In particular, if you are looking at producing charcoal in massive quantities, this will be very easy to do with Beston charcoal machines(https://www.bestoneco.com/hornos-metalicos-para-hacer-carbon/).

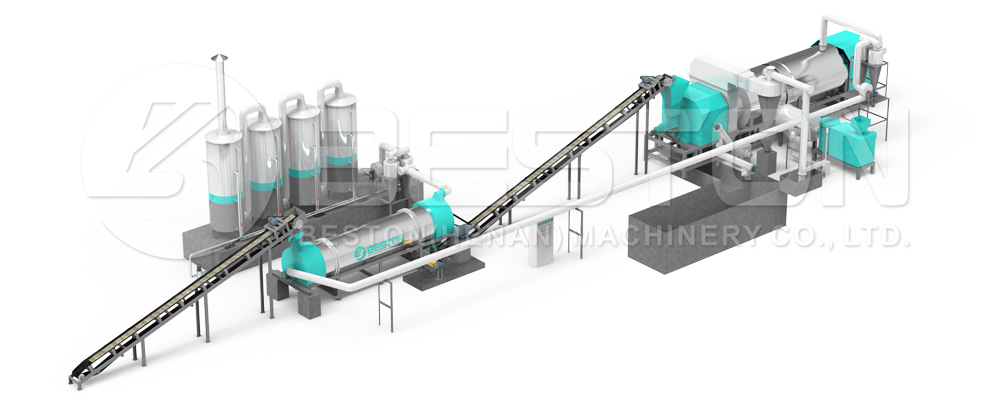

Planta de Pirólisis

Why Beston Is Such A Good Company

This is a business that is highly regarded throughout the world for producing industrial equipment(Equipo de carbonizacion). In particular, they are capable of creating machines that can easily convert many different organic materials into charcoal. An example of this would be taking sawdust, and through this conversion process, charcoal can be made. It is highly efficient, especially when using the machines from Beston that are so easy to use.

How Many Of These Would You Need?

You would likely need several of these at one facility if you are processing a large amount of material. This would enable you to process thousands of tons of waste material using just a handful of Beston machines. If you can, order multiple units at the same time, so that they can be delivered right away. You will have the ability to save money, and also start producing more charcoal than ever before with these carbonization machines.

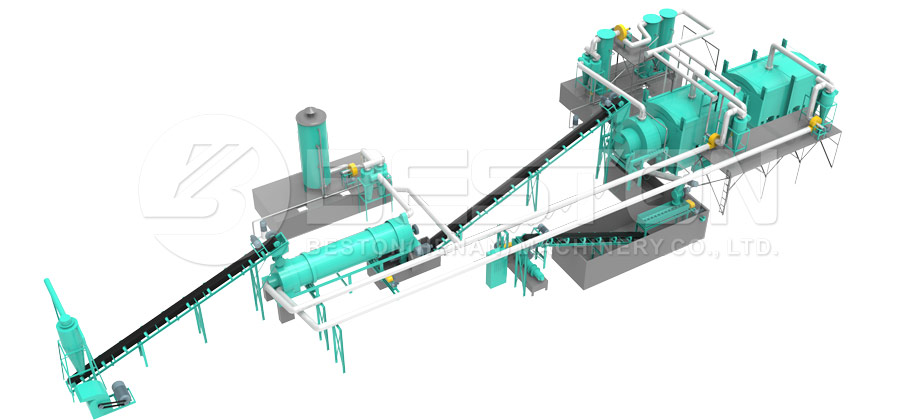

Tres en Uno–BESTON

Are These Easy To Use?

These are certainly easy to use if you have ever used a carbonization machine before. It is often designed to be set up just moments after it arrives. You will need to learn how to use the controls, where to place the material, and how long it will need to process. However, they are designed for simplicity, regardless of their size, due to the way that Beston(la compañía BESTON) manufactures them for businesses that create these byproducts. The key is to obtain at least one machine from this business to learn why so many people worldwide use them for the production of charcoal.

The very best carbonization process in the world will always occur with a Beston charcoal machine. They have refined the process substantially, making it possible for you to go through tons of material year after year. For those that have not used machines from this business in the past, you will be pleasantly surprised with your results. It really is that easy to locate a Beston charcoal machine that can create charcoal from so many different types of materials.