In the modern energy and waste management industry, pyrolysis has emerged as a promising technology for converting waste materials into valuable resources. Choosing the appropriate pyrolysis process can significantly influence operational efficiency, output quality, and overall profitability. Two main types of pyrolysis processes dominate the market: continuous and batch. Understanding their differences and advantages is crucial for making informed investment decisions.

Understanding the Basics of Pyrolysis

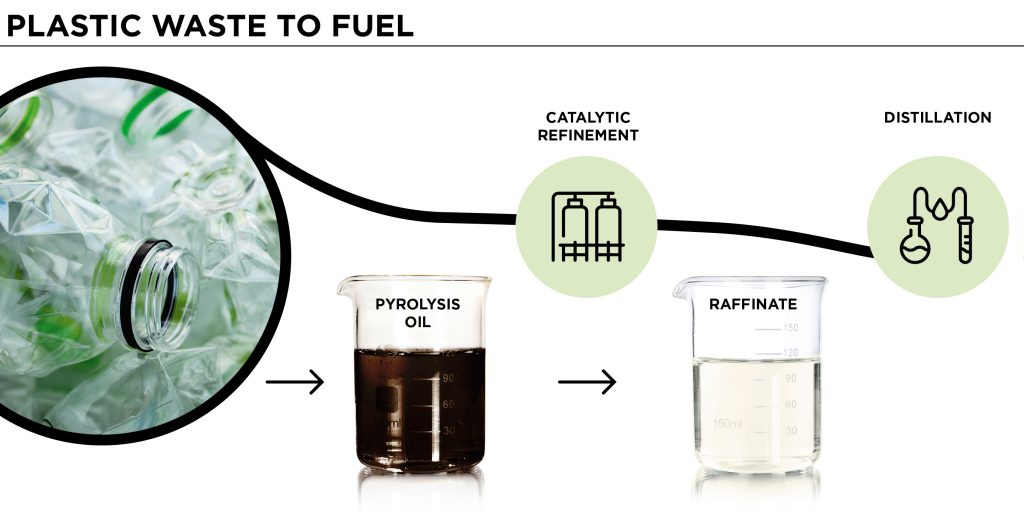

Pyrolysis is a thermal decomposition process that occurs in the absence of oxygen. It can transform various feedstocks, including plastics, tires, and biomass, into oil, gas, and char. The process type—continuous or batch—dictates how feedstock is introduced, processed, and removed, ultimately affecting production stability and economic feasibility. More introduction to the pyrolysis plant.

Key Features of Continuous Pyrolysis

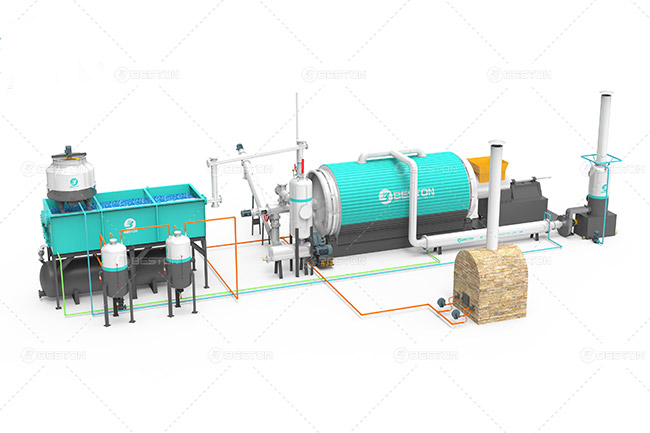

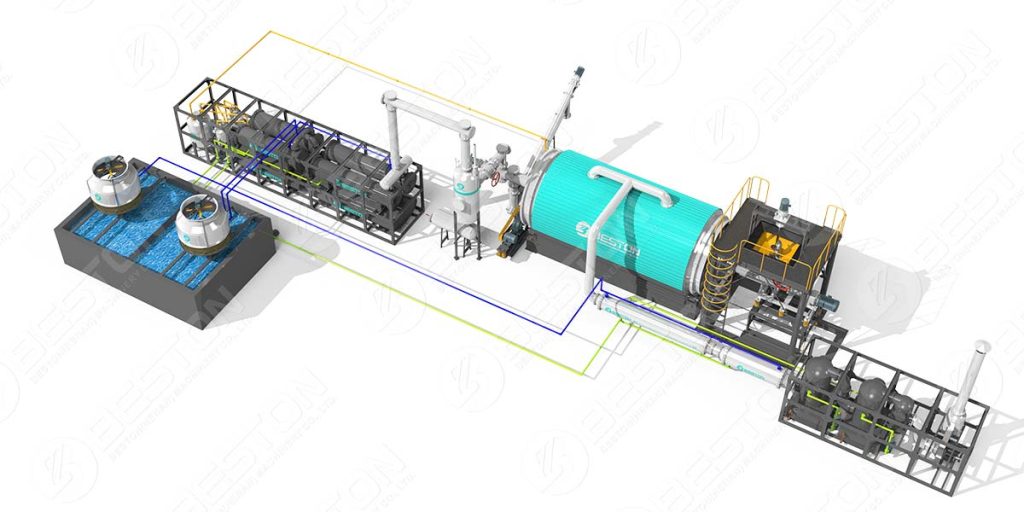

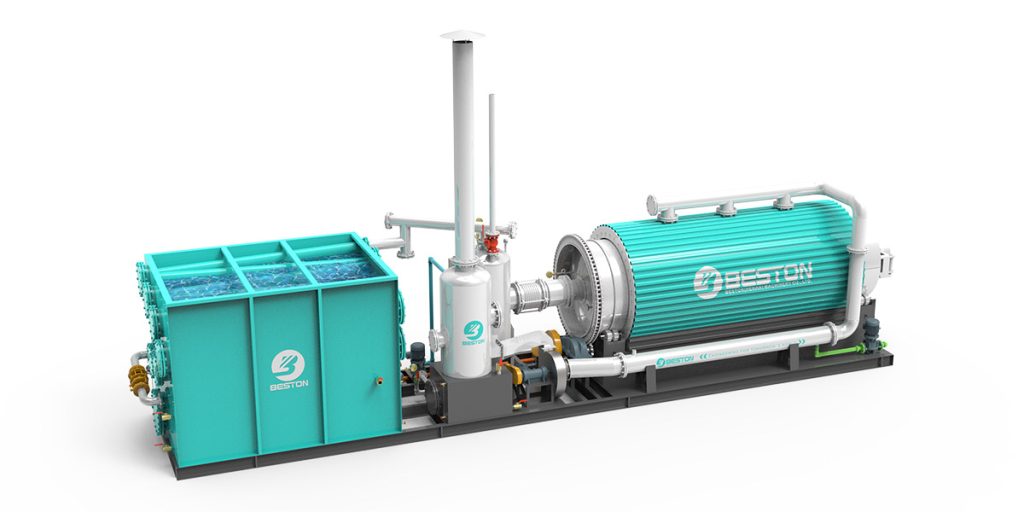

Continuous pyrolysis is designed for nonstop operation, making it suitable for industries that require high output. A continuous pyrolysis plant maintains a steady flow of feedstock into the system, allowing for consistent temperature control and uniform heating. This results in more stable product quality and reduced downtime compared to batch systems.

In addition, using a continuous pyrolysis reactor can enhance energy efficiency. Since the system operates without frequent stops, heat loss is minimized, and overall energy consumption per ton of feedstock is lower. Continuous systems are often favored in large-scale applications where long-term productivity is a priority.

Advantages of Batch Pyrolysis

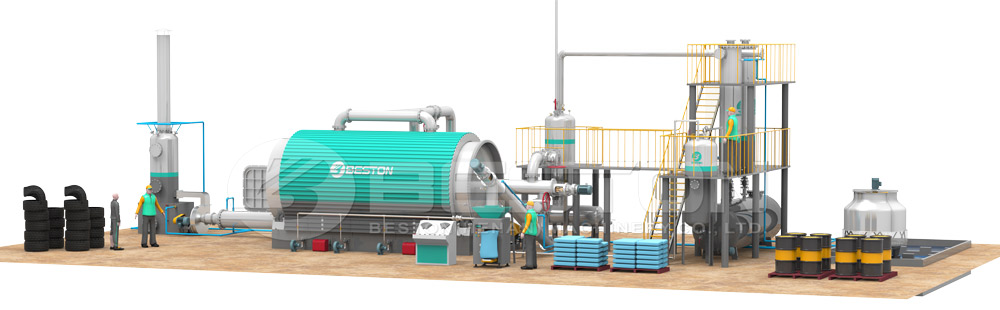

Batch pyrolysis, also known as intermittent pyrolysis, processes feedstock in discrete batches. Operators load material, heat it to the desired temperature, allow pyrolysis to occur, and then remove the products before starting a new cycle. This flexibility makes batch systems ideal for smaller operations or facilities handling diverse feedstocks with varying characteristics.

Another benefit of batch systems is their lower initial investment cost. Since batch reactors are simpler in design and operation, they can be a cost-effective solution for startups or pilot projects. They also provide greater control over reaction parameters, allowing for experimentation with different temperatures and feedstock types without major system modifications.

Economic Considerations

When evaluating continuous versus batch pyrolysis, economic factors play a significant role. Although continuous tyre pyrolysis plants and continuous plastic pyrolysis plants may require higher upfront capital, their ability to maintain uninterrupted production can lead to higher returns in the long run. Conversely, batch systems may incur lower initial costs but face higher labor and maintenance expenses due to frequent loading and unloading cycles.

Operational Efficiency and Maintenance

Continuous systems excel in operational efficiency. The steady flow of feedstock reduces temperature fluctuations, minimizes product inconsistency, and allows for automation. However, they may require specialized personnel for maintenance and monitoring, and any malfunction can disrupt the entire production line.

Batch systems offer simpler maintenance since each cycle can be fully inspected, cleaned, and adjusted. This can reduce the risk of severe operational downtime. However, frequent start-stop cycles increase wear on equipment, and manual operation may lead to variations in product quality.

Environmental and Safety Aspects

Continuous pyrolysis processes often feature integrated gas collection and condensation systems, which help reduce emissions and improve environmental compliance. Automated controls also enhance safety by maintaining optimal operating conditions and reducing human error.

Batch systems, on the other hand, require careful monitoring during each cycle to prevent overheating or incomplete pyrolysis. While they offer more manual control, they may have higher chances of emissions spikes if not managed properly.

Deciding Factors for Industry Applications

The choice between continuous and batch pyrolysis depends on several factors. Large-scale industrial operations, high feedstock volume, and a need for consistent product output generally favor continuous systems. In contrast, smaller facilities, varied feedstocks, and budget constraints may lean toward batch solutions. Evaluating operational goals, feedstock type, investment capacity, and long-term profitability is essential in making the right choice.

In summary, both continuous and batch pyrolysis offer distinct advantages and challenges. A thorough analysis of production needs, economic considerations, and operational capacity is necessary to determine which approach best suits a specific project. By carefully weighing these factors, businesses can maximize efficiency, profitability, and environmental compliance while leveraging the potential of pyrolysis technology. Beston Group – professional pyrolysis plant manufacturer.