If you are interested in tire recycling machines, you need to know what options are available on the market. There are a few different types of tire recycling machine that you can look at based on what you want the end product to be. A lot of people will look at shredding machines while others will look at pyrolysis machines.

Waste Tire Recycling Machine

Shredding Machines

One type of tire recycling machine that you can get is a shredding machine. There are 4 different levels to these machines based on the end product. The first is a TDS or tire derived shreds machine which creates the largest rubber cuts from tires.

These machines will be the first level of machine and tire shreds can be passed through the Beston Machinery machine multiple times to create smaller pieces. It is recommended that you also look at the second shredder which is the wire-free chip machine. This machine will remove steel wire from the ire shreds created by the TDS machine.

The third type of shredding machine will create crumb rubber. All of the steel and fiber will be removed from the tire shreds and uniform granules of rubber will be created. This rubber can be used in a range of industries including engineering and landscaping.

The last machine you can consider is the rubber power machine. This is considered the last level of ambient tire recycling and will produce rubber granules that are extremely small in size. The powder created can be used in a number of ways including coatings and being incorporated into asphalt.

Pyrolysis Machines

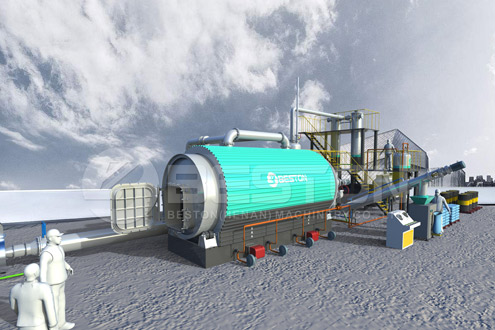

If you want to transform the tires into a different substance, you can look at pyrolysis machines. Many of these machines will transform tires into oil and this can be helpful for many industries. However, it is important to note that this will require heat and the process is not as environmentally friendly as shredding. See beston pyrolysis plant here.

These machines will heat the tires to a set temperature, generally around 100°C. The heat is slowly increased to breakdown the tires and create the end product which is wanted. These machines will have various chambers to collect the heat, cool and collect the end product.

Machine Size

The size and capacity of the machine you get will vary depending on your needs and budget. Larger machines will cost more, but will be able to handle larger quantities of tires. If you are considering a tire to oil machine, you need to consider the number of tires needs to create the oil that you want. Get pyrolysis plant cost estimate here.

This is something that you will have to talk to the manufacturer or retailer about. Choosing the right type of machine is important, but the size and capacity are vital for continued usage.

There are many different tire recycling machines on the market that you can consider. The primary point when looking at these machines is to determine the output that you want. Some machines will create oil from the tire while others will create recycled rubber instead. The size and capacity will also need to be considered.