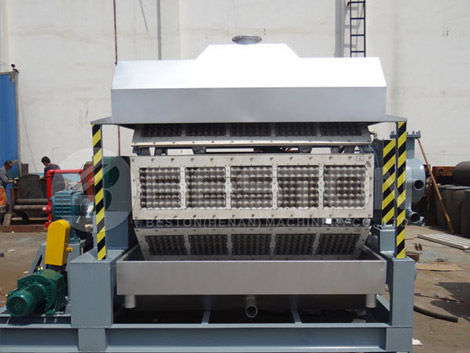

With the ever-growing demand for affordable and eco-friendly packaging materials, apple trays have become popular for the transportation and storage of apples and other fruits. With such demand, owning an apple tray making machine can have many benefits for you, including guaranteed profits for your product. These machines use waste as the raw material to make apple trays through pulping, mold formation, drying, and packing. Some of the most common models for these machines include the BTF-1-3, BTF-3-4, BTF-1-4, BTF-4-8, BTF-4-4, BTF-5-8, and the BTF-5-12. These models can produce 1000-6000 pieces of apple trays in an hour and therefore come in handy where there’s a high demand for the apple trays.

apple tray making machine

Consideration to Make Before Buying an Apple Tray Making Machine

If you are out in the market for an apple tray making machine, it is important that you keep these things in mind for the best purchase:

Productivity of Machine

It is important to consider your production needs, that is, how many apple trays you want to produce per hour. Apple tray making machines come in various categories, including manual, semi-automatic, and fully-automatic machines. Manual apple tray making machine can produce 1000-1500 pieces per hour. The semi-automatic machines can produce 2000-4000 pieces an hour, while the fully-automatic ones can produce 4000-6000 pieces in an hour. With such numbers in mind, you can decide on the type of apple tray making machine that best suits your production needs. Click here to know more: https://eggtraymakingmachine.net/egg-tray-making-machine-in-india/.

Specifications

Apart from the model and production capacity, it is also important to keep in mind other specifications such as electricity or fuel consumption, required labor force, and consumption of raw materials. Considering these features helps streamline your apple tray production process since you can align all the resources and requirements for the production of apple trays.

Therefore, it is important to choose an apple tray-making machine that matches your electricity supply, labor force, and raw materials. That way, you don’t have to scale upwards to suit the specifications of the machine.

The price is the determining factor in any purchase, and it is no different from an apple tray making machine. Do your research on the internet for the best prices to avoid overspending. If you wish to import your apple tray making machine, it is also important to incorporate shipping costs.

Experience of Manufacturer

The best way to get a top-quality apple tray making machine is buying from an experienced manufacturer. These are companies that have been in the manufacturing industry for a long time and are therefore experienced. With such manufacturers, you can expect the best paper egg tray machine since they have to protect their brand.

apple tray

Benefits of Apple Tray Making Machines

Economic

While their initial purchase cost may be high, these machines are economical to use in the long run. They use cheap raw materials, are mostly energy-saving, and have low maintenance costs.

Multi-Purpose

Apart from producing apple trays, these machines can use different molds to give various final products such as egg cartons, egg trays, bottle trays, coffees cup trays, and shoe supports.

What’s more, these machines are environmentally friendly and simple to operate. This way, you don’t have to worry about hiring an expert to operate it. More information on the blog: http://bestonblog.blog.fc2blog.us/.