The world is facing an environmental crisis, with plastic pollution and overflowing landfills posing significant challenges. Plastics are ubiquitous in our daily lives, and their disposal has become a global issue. In this era of heightened environmental consciousness, pyrolysis has emerged as a promising solution to address both plastic pollution and the burden of landfills. In this comprehensive exploration, we will delve into the world of plastic pyrolysis machine, understanding its role in tackling these environmental crises, and its potential to unburden the Earth from plastic waste and landfills.

The Plastic Predicament

Plastics have revolutionized modern life with their versatility and convenience. However, the persistent nature of plastics, combined with their widespread use and improper disposal, has given rise to a global plastic pollution crisis. Single-use plastics, microplastics, and plastic waste in oceans and waterways are causing irreparable harm to ecosystems, wildlife, and human health.

Landfills, on the other hand, are reaching their limits in many regions, and their negative environmental impact is substantial. Landfills emit methane, a potent greenhouse gas, and can contaminate soil and groundwater. Finding sustainable solutions to these crises is paramount.

Enter Pyrolysis

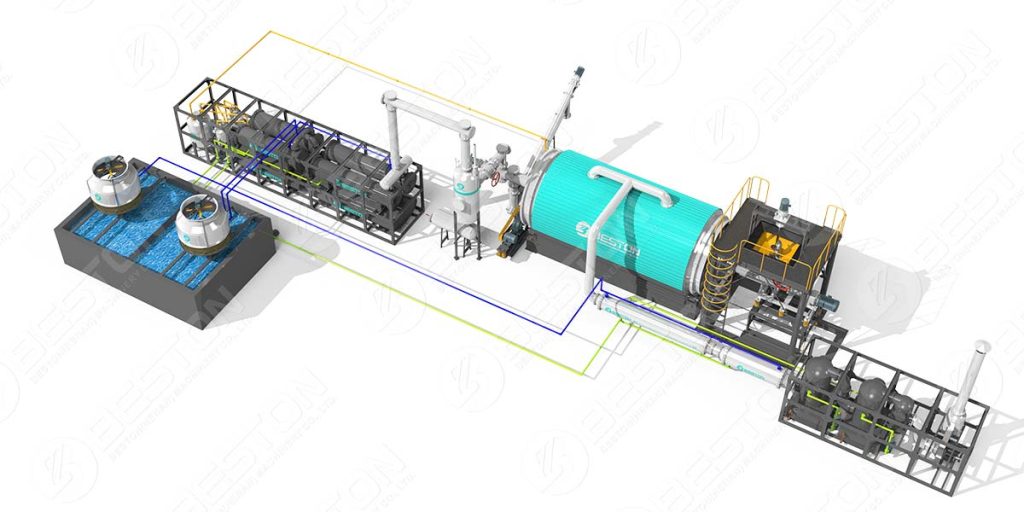

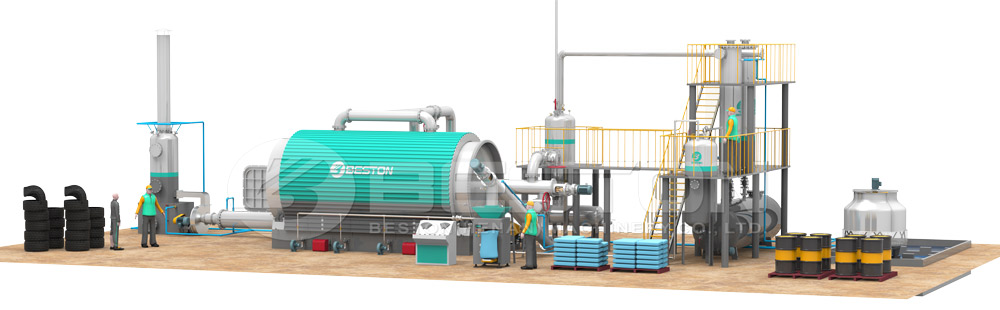

Pyrolysis is a thermal decomposition process that can convert various organic materials, including plastics, into valuable products in the absence of oxygen. This process not only addresses plastic waste management but also mitigates the negative impacts of landfills. The key steps in pyrolysis include:

Feedstock Preparation: Plastic waste, which can include various types of plastics, is collected, sorted, and prepared for the pyrolysis process.

Heating and Decomposition: The prepared plastic waste is subjected to high temperatures (typically between 350-700°C) in a controlled environment with limited oxygen in waste plastic to fuel conversion plant. Under these conditions, the plastic waste decomposes into useful products.

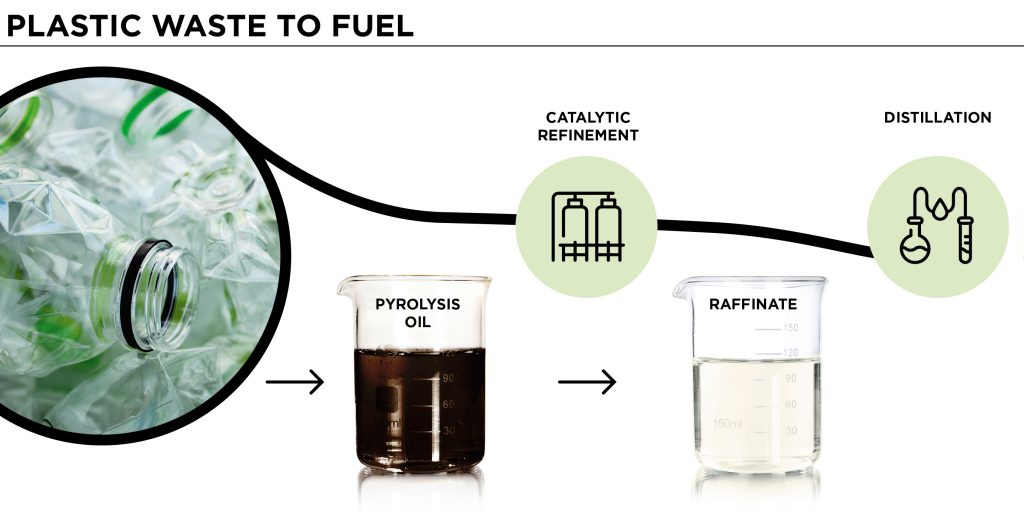

Vaporization and Product Collection: The thermal decomposition of plastics yields gas, liquid, and solid products. These products can include syngas, pyrolysis oil, and solid char, which can further be processed into valuable materials.

The Environmental Promise of Pyrolysis

Pyrolysis offers a myriad of environmental benefits that make it a key player in addressing plastic pollution and landfill overflow:

Plastic Waste Diversion: Pyrolysis enables the diversion of plastic waste from landfills and incineration, reducing the burden on these waste disposal methods.

Mitigation of Greenhouse Gas Emissions: By converting plastics into useful products, pyrolysis helps reduce the emission of methane and other greenhouse gases associated with landfills.

Recovery of Valuable Resources: Pyrolysis can recover valuable resources from plastic waste, including syngas for energy generation, pyrolysis oil for various applications, and solid char, which can be used in multiple industries.

Circular Economy Promotion: Pyrolysis supports the transition towards a circular economy by recycling plastics and reusing the resulting products.

Marine and Ecosystem Protection: By diverting plastics from the environment, pyrolysis helps protect marine life and ecosystems from the harmful effects of plastic pollution.

Applications of Pyrolysis

Pyrolysis has a broad range of applications, each contributing to the unburdening of the Earth from plastic pollution and landfills:

Plastic Recycling: Pyrolysis can convert mixed plastic waste, including hard-to-recycle plastics, into valuable products, effectively closing the plastic recycling loop.

Waste-to-Energy: The syngas generated during pyrolysis can be used as a renewable energy source for electricity generation and heat production.

Pyrolysis Oil: The pyrolysis oil can be used as a feedstock for the production of chemicals, transportation fuels, and lubricants.

Carbon Black Production: Solid char from pyrolysis can be processed to create high-quality carbon black, used in various industries, including tire manufacturing and ink production.

Soil Amendment: Biochar, a type of solid char produced through pyrolysis, can be added to soil to enhance fertility and carbon sequestration, reducing the need for chemical fertilizers.

Economic Considerations

The economic feasibility of plastic to oil machine price in addressing plastic pollution and landfills depends on several factors:

Feedstock Availability: The consistent supply of plastic waste is crucial to the success of pyrolysis operations. Efficient collection and preparation are essential.

Pyrolysis Technology: The choice of pyrolysis technology affects capital costs, operational efficiency, and the quality of the end products.

Market Dynamics: The prices and demand for pyrolysis products, such as syngas, pyrolysis oil, and carbon black, influence the economic viability of pyrolysis projects.

Government Incentives: Government policies, subsidies, and incentives for waste management and renewable energy initiatives can significantly impact the economic feasibility of pyrolysis.

Local Regulations: Compliance with local regulations and waste management laws is essential for the operation of pyrolysis plants.

The Way Forward

As technology advances and environmental awareness grows, pyrolysis is increasingly recognized as a powerful solution to address plastic pollution and landfills. By diverting plastics from landfills, reducing greenhouse gas emissions, and recovering valuable resources, pyrolysis offers a sustainable path forward.

Education, public awareness, and investment in pyrolysis technology are essential to its widespread adoption. Government support, in the form of policies, incentives, and regulations, can further accelerate the transition to a more sustainable waste management and energy generation paradigm.

Conclusion

Pyrolysis stands as a key player in the endeavor to unburden the Earth from the dual challenges of plastic pollution and overflowing landfills. Its ability to convert plastic waste into valuable resources, while mitigating the environmental impacts of landfill disposal, makes it a promising solution in the fight against climate change and environmental degradation.

With the right investments, policies, and public awareness, pyrolysis can become an integral part of the global effort to protect the environment, conserve resources, and promote a circular economy. As we move towards a more sustainable future, pyrolysis has the potential to significantly alleviate the plastic pollution and landfill crises, offering a cleaner and greener world for generations to come.