The modern world faces lots of challenges, not least of which is waste management and it becomes a matter of great concern for a country when waste disposal is not properly managed. Effective waste management and efficient recycling can avoid many health risks, reduce global warming and make the world a better place. For this reason, a waste separation plant was developed to sort waste into various categories which makes waste management easier and more efficient.

Garbage Separation System

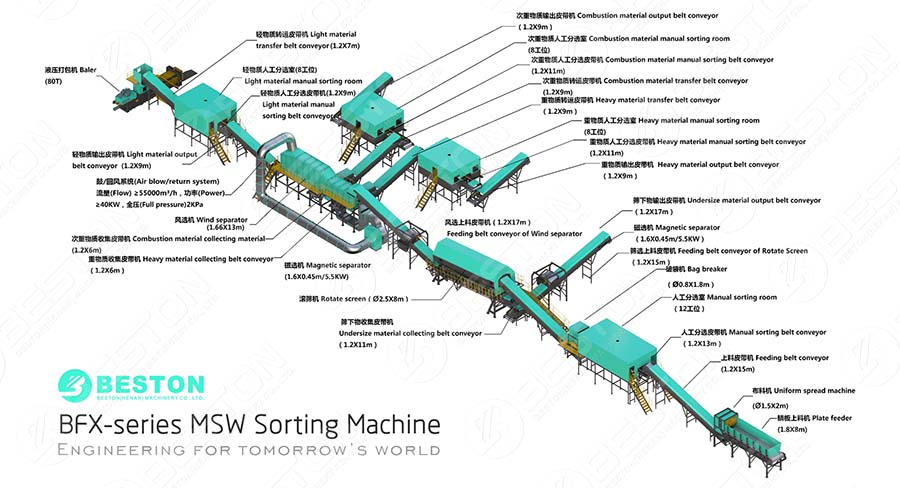

A fully automatic waste segregation machine can sort materials such as plastic, paper, metal, and glass with an electro-mechanical system that uses a micro-controller and an operational amplifier. Conventional sensors are used for glass and metal sorting, and LDR and laser sensors are used for paper and plastics to make recycling more efficient. A counter and weight sensor is used to calculate the number of materials sorted. A fully automatic waste segregation machine effectively transforms a conventional waste management plant into a Smart system that deals with waste in a modern, efficient, and cost-effective way.

An automatic waste segregation machine uses a variety of means to sort different types of materials such as metal, plastic, stone, brick and other substances from garbage sources to improve the recycling of waste material. Once the waste has been separated it is easier to identify which materials can be further processed and reused to manufacture new products, for example, charcoal carbonization furnace for organic waste management. A waste segregation machine uses reduction processing to turn waste into treasure.

Garbage Segregation Plant in China

Final Products Obtained from Automatic Waste Segregation Machine

– Plastic waste is packed by an automatic packing machine and sold directly or cleaned and crushed into granules by a plastic recycling machine. A pyrolysis plant can convert it into black carbon and fuel. PET plastic waste can be transformed into flakes and re-processed to produce fibers for use in clothing or for inner material for pillows and bolsters.

- Organic waste is used to generate bio-gas through a fermentation process.

- Combustible items such as wood can be turned into RDF for gasification generation.

- Green organic matter such as grass, leaves, and straw can be turned into charcoal powder or briquettes to make fire.

All of these can be realized with the help of Beston Machinery Co Ltd.

Main Features of Waste Segregation Equipment

- The automated sorting system is equipped with a belt conveyor to uniformly distribute waste.

- The sturdy structure and configuration of the equipment reduce labor intensity and improves work efficiency.

- The fully automatic operation eliminates manual work and avoids worker mistakes.

- A fully-sealed waste sorting process reduces pollution.

- All separated waste obtained by segregating materials can be used to either produce final products for re-use or be disposed of without generating pollution.

The automatic waste sorting machine is equipped with a surveillance system that monitors the processing procedure to ensure that everything runs safely and smoothly.

An intuitive PLC control system displays equipment action such as running, stopping, fault display, and other actions for safe monitoring of the system.

Each automated part of the system is equipped with both a manual and automatic switch and an emergency stop device for the safety of workers and equipment. Each belt conveyor is also equipped with an emergency stop device.