Biochar production, through the process of pyrolysis, has become a critical technology in both waste management and carbon sequestration efforts. As the demand for biochar grows in agricultural, environmental, and industrial applications, optimizing the cost structure of biochar production projects has become increasingly important. Effective cost management in a pyrolysis plant not only ensures profitability but also enhances the sustainability of biochar production as a long-term solution. Key cost drivers include feedstock procurement, energy consumption, labor costs, and equipment maintenance. Optimizing these areas is crucial for maximizing the financial viability of biochar production facilities.

Feedstock Procurement and Logistics

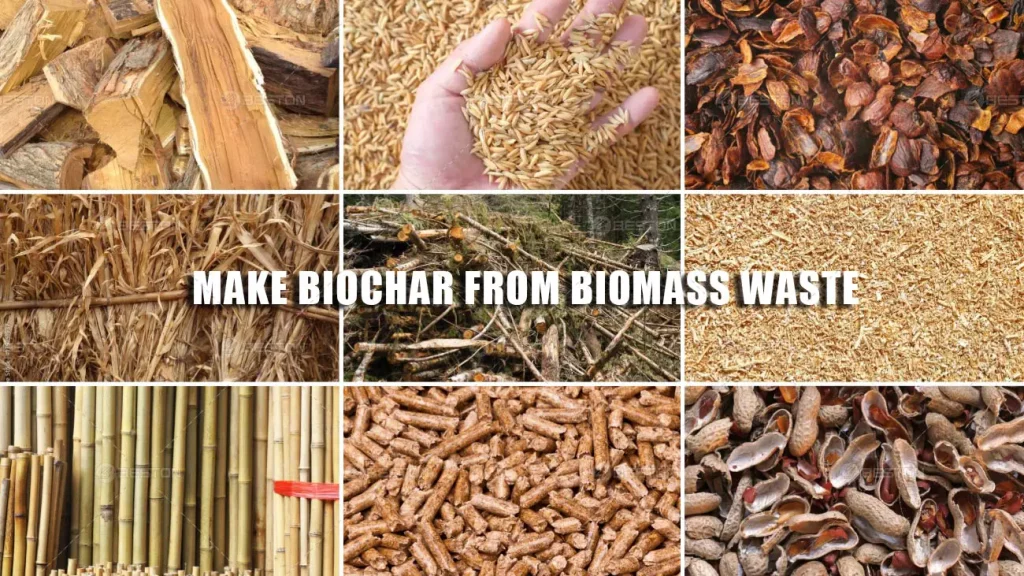

The cost of feedstock is often the largest single expense in biochar production. Feedstock can come from a wide range of organic materials, including agricultural waste, forestry residues, and urban organic waste. The cost of feedstock depends on the proximity of the material to the plant, the method of collection, and the preprocessing requirements.

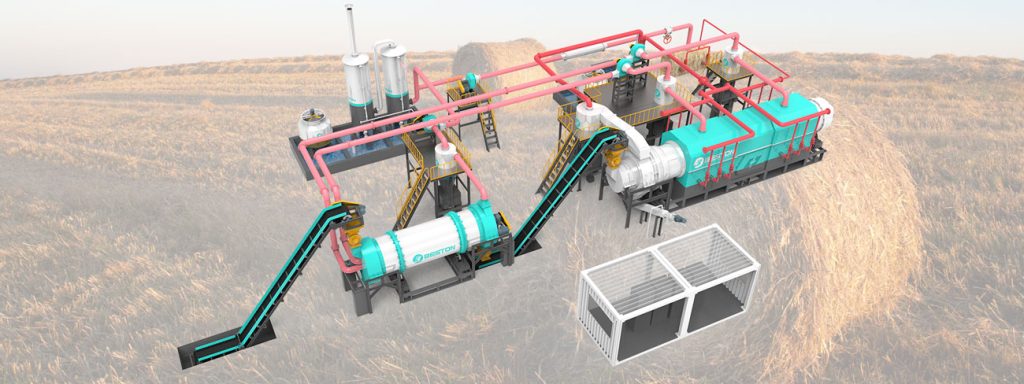

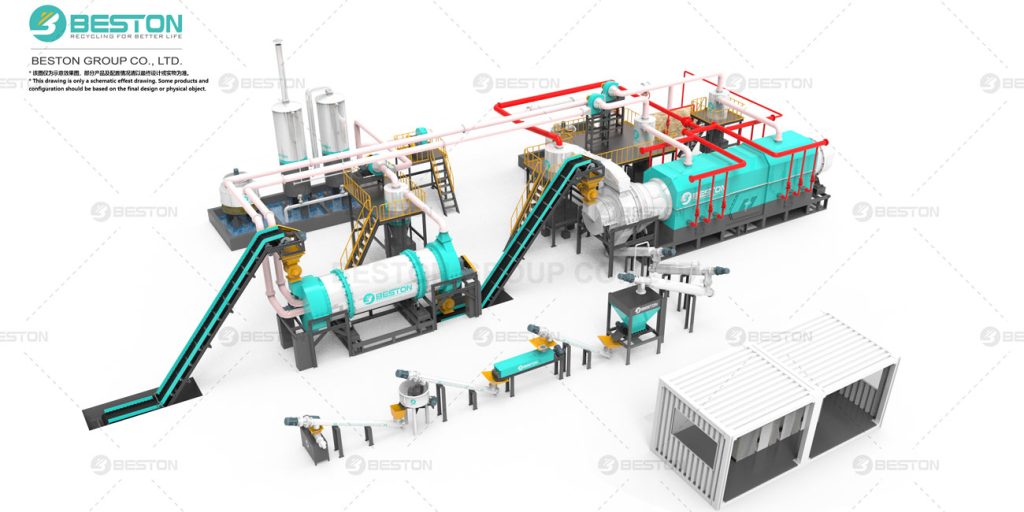

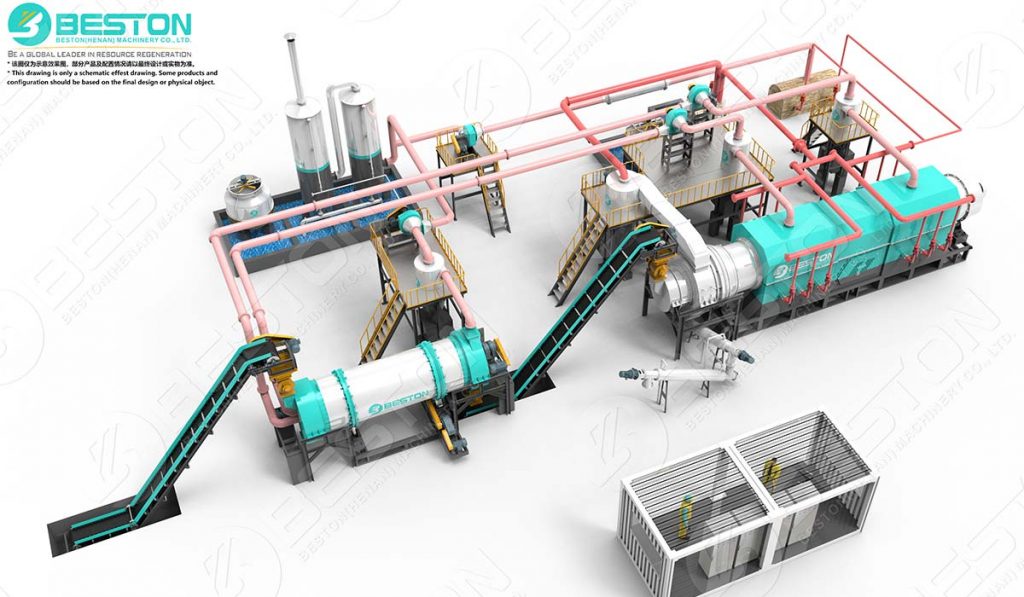

Optimizing feedstock procurement involves identifying reliable and low-cost sources, potentially by leveraging waste streams from local industries or partnering with agricultural producers. Strategic site selection for the biochar making machine can reduce transportation costs and improve feedstock availability. Additionally, preprocessing activities such as drying, shredding, and sorting can be optimized using energy-efficient equipment or waste heat recovery systems from the pyrolysis plant itself, thereby reducing overall feedstock preparation costs.

Another approach is blending different types of feedstock to optimize carbon yield and reduce the need for expensive, high-quality materials. By ensuring uniformity in the feedstock’s moisture content and particle size, it becomes easier to maintain consistent pyrolysis conditions, improving the efficiency of the process and ultimately reducing waste.

Energy Consumption and Efficiency

Energy usage is another major operational cost in biochar production. The pyrolysis process requires significant heat input, typically generated by burning a portion of the biomass itself or using external fuel sources. Optimizing energy consumption begins with selecting the appropriate pyrolysis technology. Continuous pyrolysis systems, in particular, tend to be more energy-efficient than batch systems due to their ability to maintain constant temperature and process flow.

One of the most effective strategies for reducing energy costs in a biochar pyrolysis machine is the implementation of energy recovery systems. By capturing and reusing the heat produced during the pyrolysis process, the facility can significantly reduce its reliance on external energy sources. Syngas, produced as a byproduct of pyrolysis, can be utilized to fuel the plant’s heating system or converted into electricity, further reducing operational costs.

Furthermore, optimizing reactor design can also enhance energy efficiency. Advanced reactor configurations such as fluidized-bed or rotary kilns allow for more even heat distribution, minimizing energy losses and reducing fuel consumption. Adding insulation materials to reactors and piping systems can further reduce heat losses, ensuring that energy is retained within the system for maximum efficiency.

Labor and Workforce Management

Labor costs in biochar production can be controlled by leveraging automation and digital process control. A well-designed pyrolysis plant should incorporate automated feedstock handling, temperature control, and product handling systems to minimize manual labor requirements. This not only reduces labor costs but also improves operational consistency and safety.

Investing in digital monitoring and control systems can also optimize plant performance, providing real-time data on reactor conditions, energy consumption, and product yield. With predictive maintenance capabilities, operators can identify potential issues before they lead to costly downtime, extending the lifespan of critical equipment and reducing repair expenses.

Although automation plays a key role in labor cost reduction, training and maintaining a skilled workforce remain essential. Operators must be knowledgeable in the handling of advanced carbonization machine and emergency protocols. Ensuring adequate training while minimizing personnel levels ensures an efficient and cost-effective workforce.

Equipment and Maintenance Costs

The equipment used in a pyrolysis plant is subject to high thermal stress and wear, especially in continuous operations. Regular maintenance is crucial to ensure plant reliability, but it can also be costly. To minimize maintenance expenses, the selection of high-quality, durable equipment made from materials resistant to corrosion and high temperatures is essential. Additionally, preventive maintenance programs that include scheduled inspections and performance analysis can help avoid expensive repairs and downtime.

Incorporating predictive maintenance tools, such as sensors and data analytics, can further optimize maintenance practices. These tools monitor equipment health and anticipate failures, reducing the frequency and cost of unscheduled maintenance. Over time, such systems can significantly extend the life of critical components and improve overall plant performance.

Strategic procurement of spare parts is another important aspect of cost optimization. Bulk purchasing or establishing partnerships with equipment manufacturers can reduce per-unit costs and provide quicker access to essential parts when needed. For the best biochar production solutions, please visit: https://bestonmachinery.com/

Product Diversification and Revenue Streams

Biochar, the primary product of pyrolysis, is used in various applications, from soil amendment to carbon sequestration. However, biochar production also generates valuable by-products such as syngas and bio-oil, which can further enhance revenue streams. The market for these by-products continues to grow, with syngas being used as an energy source and bio-oil serving as a feedstock for chemical production or renewable fuels.

By diversifying product offerings, a pyrolysis plant can mitigate risks associated with fluctuating biochar prices. Developing by-product markets, such as converting syngas into electricity or bio-oil into renewable diesel, provides additional revenue streams that contribute to overall profitability.