In the continually evolving realm of industrial processes, the domain of charcoal making machines is undergoing a significant transformation. Stepping into the future, the symbiosis between inventive machine design and enhanced efficiency stands out as the hallmark of advancement in the charcoal manufacturing sector.

Precision Engineering Redefined

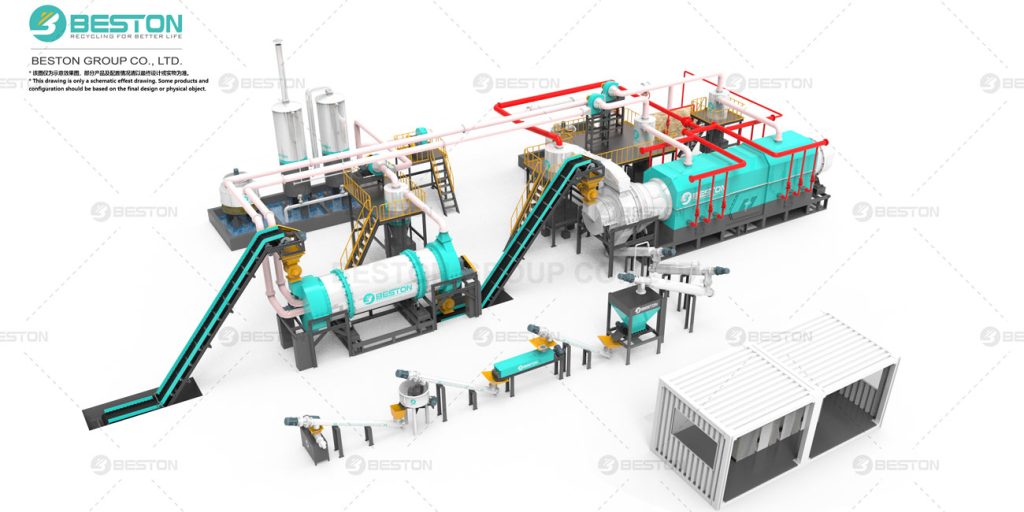

Charcoal making machine has transcended their conventional limitations, evolving into precision-engineered marvels. The integration of cutting-edge technologies such as Artificial Intelligence (AI) and Internet of Things (IoT) has revolutionized the manufacturing landscape. These machines, armed with advanced sensors and actuators, operate with a level of precision that was once deemed unattainable.

The heartbeat of these modern marvels is a sophisticated control system that orchestrates every facet of the charcoal production process. From the initial carbonization of raw materials to the final product’s packaging, the charcoal making machine orchestrates a symphony of mechanical prowess and digital finesse.

Eco-Friendly Charcoal Production

The contemporary emphasis on sustainability has permeated the charcoal manufacturing sphere. The latest generation of charcoal making machines is designed with eco-conscious principles at their core. Advanced filtration systems eliminate harmful by-products, ensuring that the manufacturing process aligns seamlessly with environmental regulations.

One notable advancement is the utilization of carbonization technologies that optimize energy consumption. This not only reduces the carbon footprint but also enhances the overall operational efficiency of the machine. The quest for sustainability is not merely a trend but a fundamental driving force behind the evolution of charcoal manufacturing.

Intelligent Automation: A Game-Changer

At the heart of the future-ready wood/coconut shell/rice husk/straw/baoboo/sawdust charcoal making machine lies intelligent automation. AI algorithms analyze real-time data from sensors, making instantaneous adjustments to optimize the production parameters. This not only maximizes output but also minimizes resource wastage.

The incorporation of machine learning algorithms enables the charcoal making machine to adapt and evolve over time. This self-learning capability ensures that the machine becomes increasingly efficient with each production cycle, making it an invaluable asset in the quest for operational excellence.

Modular Flexibility for Diverse Outputs

Flexibility is the mantra of the modern charcoal making machine. These machines are equipped with modular components that facilitate the production of various charcoal products. Whether it be lump charcoal, briquettes, or activated charcoal, the adaptability of these machines ensures that manufacturers can diversify their offerings without significant retooling.

The modularity extends beyond product variations to encompass size and capacity adjustments. Manufacturers can easily scale their production output by adding or removing modules, providing a level of scalability that aligns seamlessly with market demands.

Data-Driven Decision Making

In the era of Industry 4.0, data is the currency that drives innovation. Coconut shell/rice husk/straw/baoboo/sawdust/wood charcoal making machine are no exception. Embedded sensors continuously collect data on parameters such as temperature, pressure, and material composition. This data is not merely a byproduct; it is the cornerstone of informed decision-making.

Manufacturers leverage this trove of data to optimize production processes, predict maintenance requirements, and fine-tune product quality. The marriage of data analytics and charcoal manufacturing ensures that every operational nuance is scrutinized, paving the way for a future where efficiency is not a goal but a standard.

The Road Ahead

As we navigate the uncharted waters of the future, the trajectory of charcoal manufacturing is illuminated by the glow of innovation. The journey from traditional kilns to state-of-the-art charcoal making machines is a testament to human ingenuity.

In the grand tapestry of industrial evolution, the story of wood/coconut shell/rice husk/straw/bamboo charcoal making machine emerges as a chapter of resilience, adaptability, and progress. From precision engineering to eco-conscious practices, from intelligent automation to modular flexibility, the future-ready charcoal manufacturing landscape stands as a beacon of what can be achieved when technology and ingenuity converge. The path ahead is paved with opportunities, and the future of charcoal manufacturing is undeniably bright.