It can be tough to find the right paper pulp moulding machine for your business. There are so many different brands and models to choose from, and it’s hard to know which one is right for you.

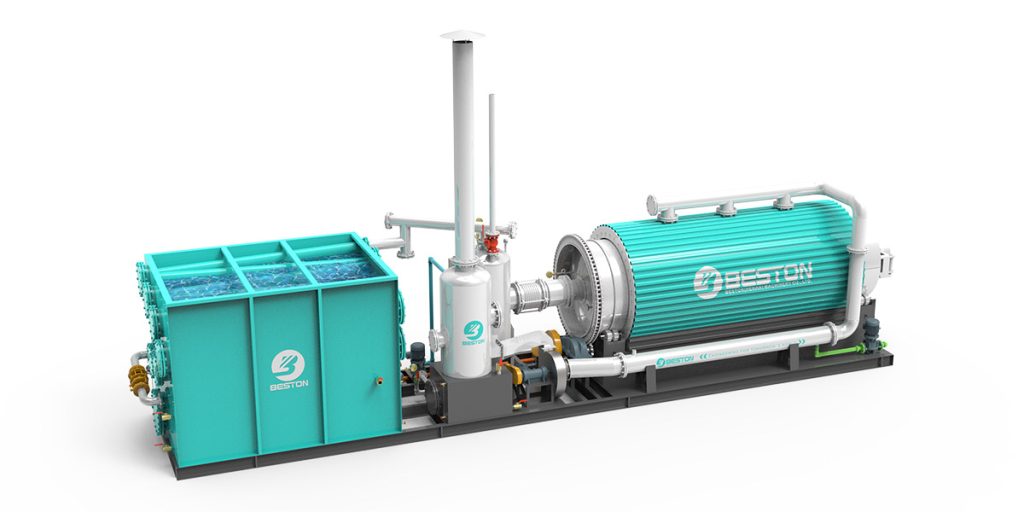

Beston Pulp Molding Machine for Sale

With the help of this comprehensive guide to paper pulp moulding machines, you can figure out which machine is best for your needs and learn how to get the most value for your money. Whether you’re a small business or a large corporation, you can find the perfect paper pulp moulding machine for you.

What is a paper pulp moulding machine and what does it do?

A paper pulp moulding machine is a machine that creates shaped products out of paper pulp. Paper pulp is a material that is made from wood fibers and is often used in the production of paper products. The paper pulp moulding machine gives the paper pulp a desired shape and can also be used to add decoration or other details to the product.

The paper pulp moulding machine is an essential tool for many businesses that produce paper products. It offers a quick and easy way to create a wide variety of shapes and can be used to produce products that are both functional and decorative.

The benefits of using a paper pulp moulding machine

Have you ever wondered how paper cups, plates, and bowls are made? The process is actually quite fascinating. Paper pulp moulding machines take a sheet of flat paper and uses heat and pressure to mould it into the desired shape. The finished product is then left to dry. This simple process can be used to create a wide variety of products, from disposable cups to sturdy plates. And because paper is a renewable resource, paper pulp moulding is a sustainable manufacturing method. That means that it’s good for the environment – and your conscience! Get a machine now: https://bestonasia.com/egg-tray-machine-manufacturers/.

How to choose the right machine for your business?

If you’re in the market for a paper pulp moulding machine, you might be feeling a bit overwhelmed. With all of the different options out there, how can you choose the right one for your business? Luckily, there are a few things you can keep in mind that will help you make the best decision.

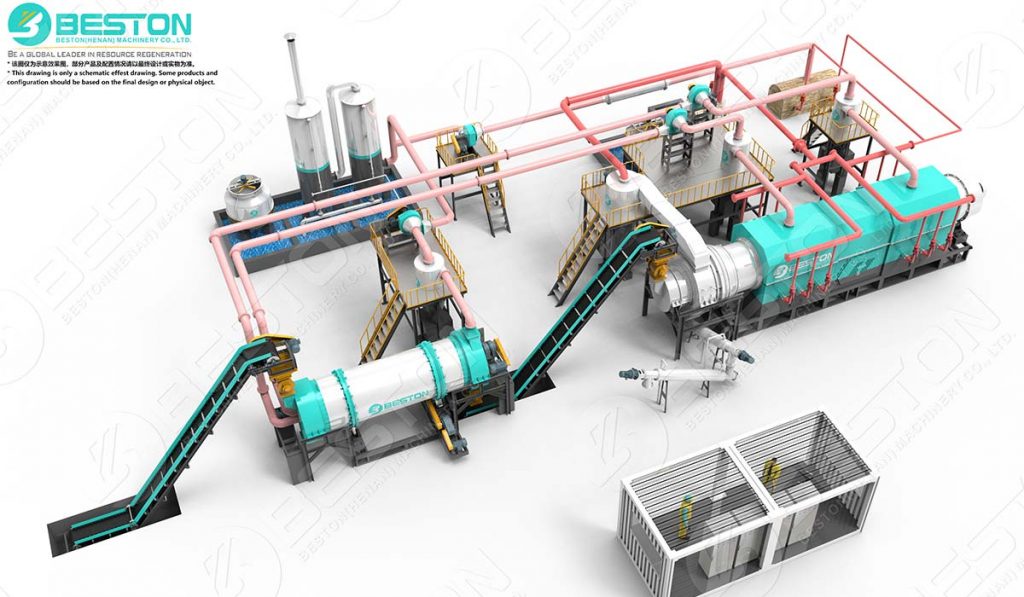

Start Egg Tray Making Business

First, think about the type of products you’ll be making. Paper pulp moulding machines come in all shapes and sizes, so you’ll need to choose one that’s capable of producing the items you have in mind. Second, consider your budget.The rotary egg tray machine prices

range from a few thousand dollars to tens of thousands of dollars, so it’s important to find one that fits within your price range.

Finally, think about the level of automation you need. Some paper pulp moulding machines are fully automatic, while others require more manual intervention. Consider your own business needs and choose a machine that will give you the right balance of automation and flexibility.

With these guidelines in mind, you’ll be well on your way to choosing the perfect paper pulp moulding machine for your business. If you still have puzzles, please contact Beston in China for more details.