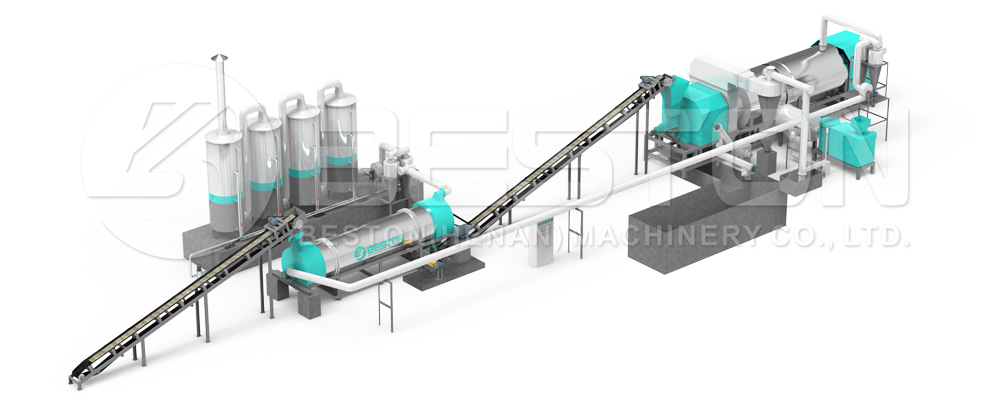

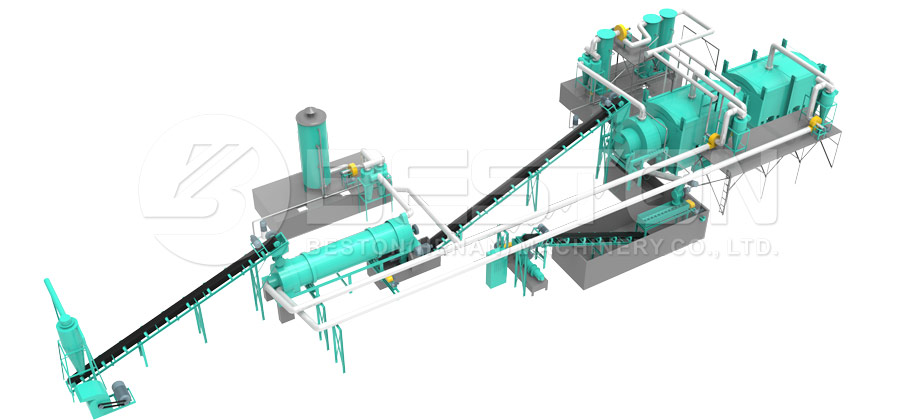

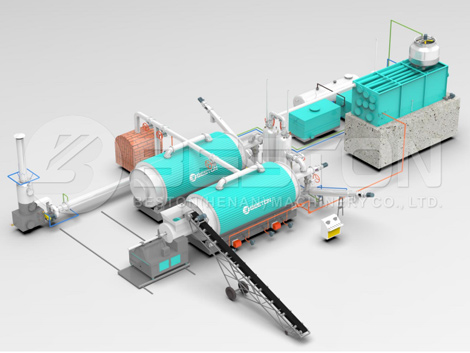

The charcoal-making machine employs powder to form briquettes in varying shapes and sizes. It comes in varying structures, all suitable for different work set-ups. One challenge that buyers of machines face is settling for the right machine due it its wide price range. Certain factors influence the charcoal making machine price. Below is detailed information on them. Knowing them gives you an upper hand to make a suitable decision for your venture. Also, you will manage to meet your client’s demands without inconveniences. Get the charcoal making machine price from manufacturers.

Get Charcoal Making Machine from Beston

Manufacturing Cost

There are numerous manufacturers within the market making these machines. Ever wondered why all of them have different selling prices? A manufacturer uses the costs incurred during production to arrive at ideal charcoal making machine price. Such include the cost of importing raw materials, government tariffs, labor, and profits. The value of raw material is one huge factor that can either increase or decrease the prices. A material like steel is costly compared to other metals. Aso, the brand that you buy from determines how much you will pay for the machine. There are known sellers with a good reputation for making the best in the industry. They take pride in sourcing quality raw, materials thus not compromising the production. The charcoal-making machine works under high temperatures, thus a need for safety measures. Their wood chips charcoal making machine comes with minimal risks for your business. Furthermore, they offer warranties to shield you in case of untimely malfunctions.

Production Capacity

Although there are many types of charcoal-making machines, they have varying capabilities regarding their production rate. The price of a device producing a ton of briquettes in an hour will cost you more than a model delivering 800 kgs within the same period. Each machine’s efficiency and structural integrity hugely influence how much it can produce in a given period. Some of these machines can meet a huge demand but require to be shut down. Others can continuously work without presenting problems. When making evaluations, it is essential to enquire about such aspects. The last thing you would want is your machine malfunctioning in the middle of a huge order. Check such factors as they may interfere with your business reputation. The best way to approach the situation is through have a sound knowledge of your business goals. Compare the findings with the functionality levels of the machine that you have in mind. See the rice hull carbonizer design.

See Aftersales Service of Beston

Power Consumption

The best machine in the market is one that can optimally function for your market. However, without proper checking, you may end up paying huge energy bills that end up taking away profits. The huge factor influencing this issue is the level of energy consumption. The charcoal-making machine price might be lower at the expense of high energy consumption. It is far much safer to settle for an energy-efficient device. The purchasing prices are going to be higher, but you enjoy affordable and smoother operations. Do you know Beston Henan? It is a reputable manufacturer.

Draft a budget as it will guide you in handling the above factors. An insight on the factors affecting prices is an assurance of choosing the best device.