Are you in the market for a new egg tray equipment? This could be one of the most valuable assets for your business as it impacts your overall productivity and bottom line. For this reason, you need to be careful when you’re looking for different manufacturers. Not all of them are created equal. You wouldn’t want to feel disappointed after buying a poor quality machine from the manufacturer that offers the lowest prices. Several factors must be considered when buying the right egg tray making machine for your company.

Paper Egg Tray Machine for Sale – Beston Group

1) Manufacturer Experience

How can you gauge the reliability of the manufacturer? A good starting point is to figure out how long they’ve been in business. Plenty of egg tray making machine manufacturers have been around for decades, which says a lot about the quality of their pulp molding machine and their overall reputation. Choosing an experienced manufacturer also means that you’ll probably find more reviews about them online.

2) Good Reputation

Of course, you also need to consider the reputation of the company. You might stumble upon manufacturers that have several years of experience under their belt, but their reputation could be less than stellar. You need to pick a company with an excellent reputation as this can have a huge impact when it comes time to claim a warranty or repair the machine.

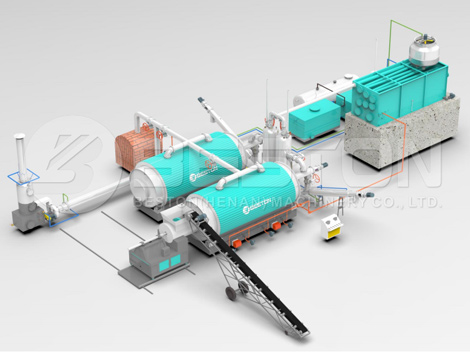

Beston Egg Tray Equipment for Sale with Good Quality

3) Location

Where the manufacturer operates is something many people fail to consider. As much as possible, choose a manufacturer that’s in close proximity to your own company. This allows you to easily go to the manufacturer in case problems arise with your egg tray making machine. Don’t forget that these machines are massive, so you’d have to pay quite a bit for shipping fee if the manufacturer you choose is far from you.

4) Budget of Paper Egg Tray Equipment

Your budget has a huge impact on your decision making process. For one, setting a budget allows you to identify what machines fall within your budget and what you can’t afford. Sometimes, it feels tempting to go beyond your budget when you see something that boasts of all the bells and whistles. But you wouldn’t want to risk wasting money which could otherwise be spent on other productive assets for your company.

5) Final Applications

You must also be crystal clear about what you expect from the egg tray making machine. If you don’t need to produce a ton of egg trays, then a small egg tray making machine could be enough for you. This would be much cheaper than their larger counterparts. But if you need something with a higher output capacity, then you have to look at the larger units. Just be sure that you can afford them and that their specifications match your unique requirements. Try to visit Beston Group China.

Buying an egg tray equipment requires careful planning. From setting your budget to talking with multiple manufacturers, you can’t afford to take shortcuts if you want to find the perfect egg tray making machine based on your particular needs. Remember that price shouldn’t be the ultimate deciding factor. It’s better to spend more money in exchange for a high-quality machine.