If you are thinking of starting a new business, you should seriously consider investing in bamboo charcoal making machines. Charcoal is in huge demand in a variety of industries including healthcare, cosmetic, pharmaceutical, agricultural and chemical industries among others. A lot of cosmetic products make use of activated charcoal for various things such as face masks, toothpaste, exfoliators and other such things. At this time, the bamboo charcoal making machine for sale is extremely useful.

Activated charcoal made from bamboo is widely used for making deodorizing products, healthcare products and other such things. Bamboo charcoal is also used in the agricultural industry due to its beneficial properties. When mixed in with soil, it makes it easy for the plants to soak in the nutrients and this is the reason, it is widely used in organic farming.

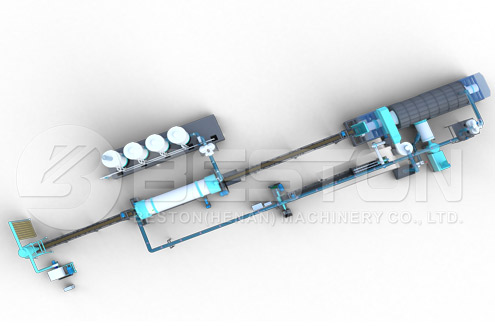

Shipment of Good Bamboo Charcoal Making Machines – Beston Group

Investing in Bamboo Charcoal Making Machines

There are a number of advantages of investing in a charcoal making machine. First and foremost, charcoal is in good demand in a variety of industries which means you will always be able to sell the charcoal for various uses. It makes for a great business if you have ample quality of the raw material available in your location. Also, it is a consumable product which means there is consistent demand for this product in various industries and if you are able to supply high quality charcoal to the buyers, they will keep coming back to you every time they want some charcoal. Besides, this machine also can be named rice hull carbonizer for sale Philippines.

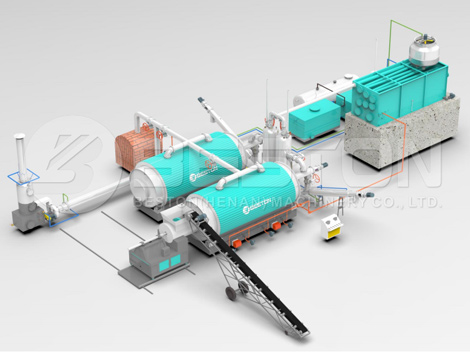

Beston Bamboo Charcoal Machine for Sale

Another advantage of investing in a charcoal making machine is that it can use a variety of raw materials for making charcoal. For instance, bamboo can be easily used along with coconut shells as well as other types of biomass for conversion into charcoal. The only thing you need to pay attention to is the carbonization process as the processing time will differ slightly for different raw materials but these machines can easily turn a variety of biomass into charcoal. There is a project for you to view.

These machines are easy to operate and do not require too much labor and maintenance especially when you invest in a high quality machine from a reputed manufacturer. Also, these machines are environmentally friendly and do not produce a lot of emissions. The traditional method of making charcoal produces a lot of smoke and other pollutants. Also, the traditional method is highly inefficient as it requires a lot of energy and does not convert even 20% of the raw materials into charcoal. On the other hand, the biomass pyrolysis machine has been designed after a lot of research and are highly efficient in the carbonization process. These machines can easily convert more than one third of the raw materials into final product and at a lower energy cost.

Overall, investment in bamboo charcoal making machines can be a great business and can bring an excellent return on your investment. However, you need to be careful while choosing a charcoal making machine. Pay attention to the features, materials used for making the machine and reputation of the manufacturer in order to get the best value for your money. Contact Beston Group (https://bestonmachinery.com/charcoal-production-machine/), a reliable manufacturer.