Iron embossing is the process of stamping shapes on an iron bar with an aim of creating an intricately shaped wrought iron bar. An embossing machine in this regard makes the whole process of embossing much easier as opposed to using brute force to create the intricate shapes. So what are the working mechanisms that the iron embossing machines use to achieve the task at hand?

Herein we explore how the embossing works, to give you an in-depth understanding of all the processes that are involved in embossing iron bar on a commercial/industrial scale.

The most prominent wrought iron embossing technique that is used across the world is the cold rolling embossing technique. It is widely used due to its ease of implementation in an industrial or commercial scale process. In this regard, the majority of the Ellsen wrought iron embossing machines that are operated around the world use the cold rolling embossing technique and technology.

Cold Rolling Embossing Technique

The cold rolling embossing techniques describe an embossing technique where cold iron bars, be it flat, round or even square shaped bars are shaped without the need of inducing heat to improve the malleability of the bars. This process makes use of high pressure to produce the required shapes. The high pressure utilized in this process is the main element that is used to transfer the shape from the dies to the bars in questions.

The Steps Involved In Cold Rolling Embossing Technique

The cold embossing machines from reputable & professional manufacturers usually have a large feeder table that allows for easier guidance and acceptance of the material to the machine. Upon placing the machine on the material on the table, users then adjust the guides according to the size of the material.

The adjustment process involves adjusting for both the height and width of the bar in question. Continuous adjustment of the guides relative to the width is particularly of great importance since it makes it easier to straighten the side before the embossing process begins.

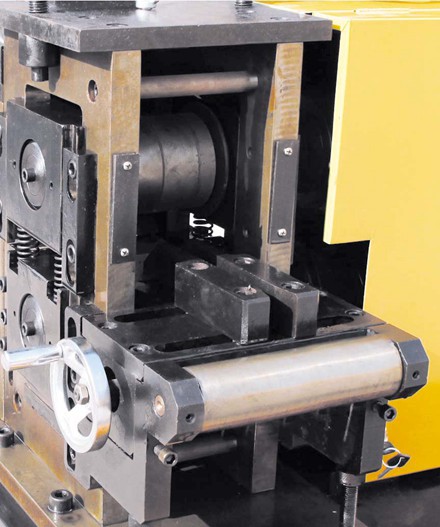

Once the iron bar is guided into the machine, an engraving die, which is typically hardened to withstand the continuous pressure it is placed under, transfers the shape and the design to the bar.

This is where the pressure we earlier mentioned comes in. The transfer of the shape and design in question occurs due to the presence of immense pressure, thus embossing the wrought iron.

After embossing, the wrought iron bar goes through a straightening section. Typically, in this section, flexible rollers are used. The rollers apply the required pressure to ensure that the iron bar comes out the other end with the desired alignment.

Elements Of A Good Iron Embossing Machine

Apart from understanding how the embossing process works, it is important to acquaint yourself with the elements to look out for while looking for an iron wrought embossing machine http://ellsenwroughtironmachine.com/cold-rolling-embossing-machine/. These elements include:

– Capacity and capability of embossing round, square and flat iron bars.

– Adjustable speed feature

– Easy maintenance

– Efficiency

– Proper straightening frameworks

With regards to automation of the machine, you should opt for a wrought iron machine like metal twist tool, wrought iron bender and hot-roll fishtail mill from reputable manufacturer like Ellsen http://ellsenwroughtironmachine.com/ that serves your needs optimally, be it an automatic or manual machine.