One of the first things that will pop up in your mind after having decided to establish your own pyrolysis plant is the tyre pyrolysis plant cost. These machines are not cheap and have a significant impact on the success of your pyrolysis business. Contrary to popular perception, the technology used in this process plays a much more important role as compared to other factors. Having said that, a number of factors affect the tyre pyrolysis plant cost. Here is what you should know about these factors:

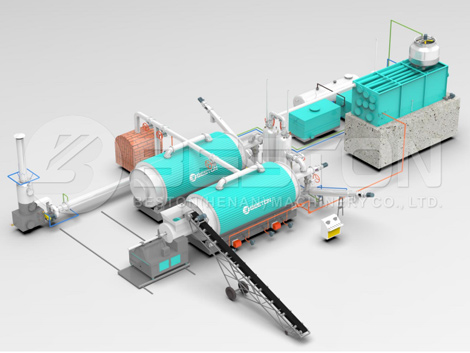

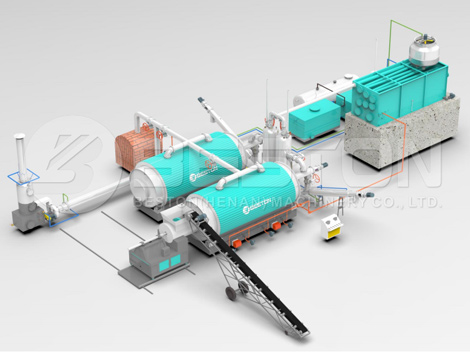

Beston Offers Good Pyrolysis Plant Cost to Customers

Design

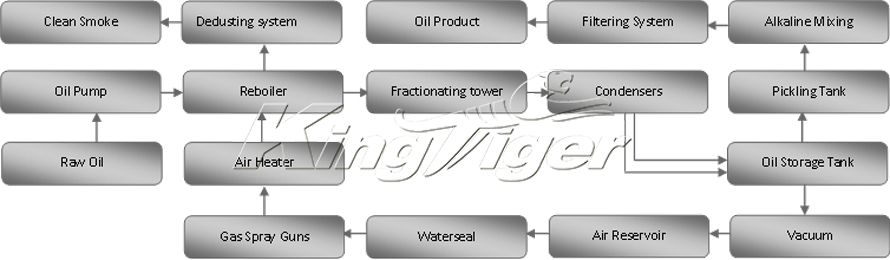

Viable pyrolysis technology has existed for a long time. However, a number of improvements in the process have taken place over the past few decades. It has resulted in more efficient and better pyrolysis plants. However, not all the companies making these machines invest in research which means you cannot expect every manufacturer in the space to deliver the latest technology.

Buying a plant equipped with the latest technology brings with it a number of advantages in terms of better efficiency, better utilization rate, better automation levels, and certain other important benefits. Naturally, these benefits come at a price. A plant equipped with the latest technology is likely to cost more as compared to a plant still using technology invented in the 1970s. Having said that, plants with modern design should provide a much better return on your investment. This is why it is recommended by experts to invest in the latest technology. See the tyre pyrolysis project report.

Country of Origin

One of the things that can help you save a substantial amount of money when buying a pyrolysis plant is considering both local and foreign sellers. Don’t worry about the quality or after-sales service as many foreign suppliers have built up a good network of service centers in various countries. Also, many of these foreign suppliers have established a good reputation in terms of quality products and excellent after-sales support.

Having said that, not every foreign supplier is up to the mark when it comes to customer service and quality of products. You will need to do some research to find manufacturers that offer a good product and back it up with excellent after-sales support. Or you choose this skid mounted tyre pyrolysis plant.

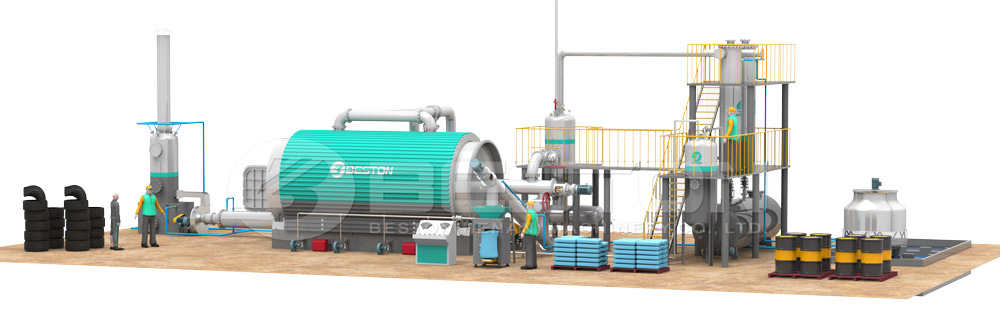

BLJ-16 Tyre Pyrolysis Plant Shipped to Saudi Arabia

Used or New

A secondhand or used pyrolysis plant is usually available at a fraction of the price of a completely new and modern plant. However, the service life of a used plant is not that long and you would also have to spend a substantial amount of money on proper repairs and maintenance in order to keep the plant running at optimum efficiency. It is a good option if you want to get started in this business with a lower capital spend as compared to investing in a completely new pyrolysis plant.

To conclude, a number of factors affect the cost of a tyre pyrolysis plant including its design, country of origin as well as whether you choose to buy a used plant. Whatever decision you make, do not choose a plant based on only its initial price. Experts recommend choosing a pyrolysis plant China equipped with modern design, the latest technology, and a high level of automation. It will help you in establishing a solid foundation for long-term success in this business.