There are many waste products that you can process through a pyrolysis plant to generate revenue for your business. These waste products may include sludge, raw sewage, and organic waste that results from harvesting crops. Instead of having this removed at a cost, you can instead process this so that you can make some extra money. To do this, you must first find a business that is currently selling these products that can offer you a very reasonable cost. Let’s discuss how they work and what the average waste pyrolysis plant cost.

Pyrolysis Plant

An Overview Of How These Plants Work

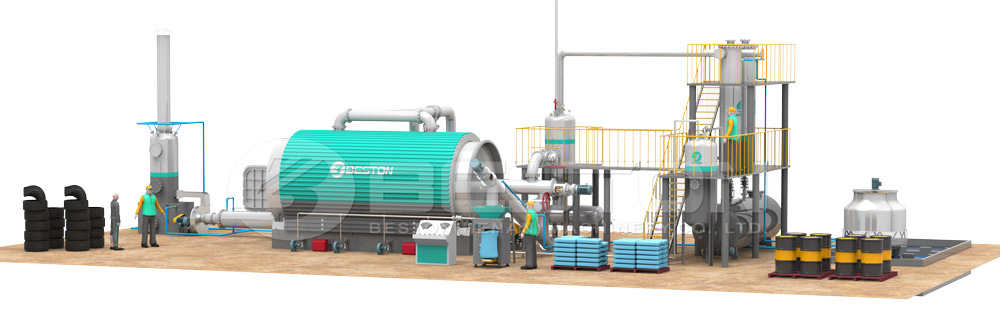

These plants are very unique for a couple of different reasons. First of all, they serve a very specific function. As mentioned before, they are able to convert waste material into charcoal. This is a material that can be sold to people that use it for fuel. Charcoal is in demand all over the world. Therefore, wherever you happen to be you, there will be a market for it. This material is placed into a pyrolysis reactor. Once it heats up after extracting the oxygen, it will then convert those materials into charcoal. Click here to know more about Beston Machinery.

How Much Do These Cost On Average?

The prices for these will vary depending upon where you live and how large the actual plant will be. For example, if you are getting one of the largest ones that can process tons of material every day, you will be paying six figures for one of these facilities. There is also the added cost of having it shipped to your location. There are many components that you will have to buy. This will include the pyrolysis reactor, conveyor belt system, and machines that can prepare the material to go through the pyrolysis reactor.

The price that you will pay is usually dependent upon its size. However, it also depends on where you start looking. In countries like China where the cost of developing these pyrolysis plants is lower, you will pay a much smaller price then you would pay in other countries. You could start with something smaller if you would prefer. This could help you save thousands on the initial cost. You must also look at the different specifications for each one to make sure you are making the right choice for tire pyrolysis machine.

Pyrolysis Plan To South Africa

Specs To Consider Before Making Your Purchase

There are many specifications to consider before you make a purchase. For example, it is important to know the operating pressure of each unit. You need to know if it is constant or if it is going to fluctuate. The total power consumption should also be considered. They may use as much as 70 kW of power or more every hour. This can cut into your overall profits. Finally, consider the pattern, heating materials, reactor size, and the raw materials that you are able to use.

This evaluation process can be very helpful in making the right choice. If you are using more than one type of waste material, you should get one that can be utilized for all of it. Don’t forget to ask about the hourly feeding capacity as this reflects directly on how much charcoal you will be able to produce. Once you have a price quote that looks optimal, consider purchasing that before someone else does. These are in high demand, and once you have your set up, you will see why these can be so profitable. Visit the tyre to oil plant here.