You can find many companies that can produce egg tray making machines in India and China. These are necessary because of the high production of eggs all over the world. You may find the egg tray machine price in India and China is lower. Keep reading for more tips to help you get a suitable egg tray machine for business.

Egg Tray Machine in India

Why Should You Automate This Process?

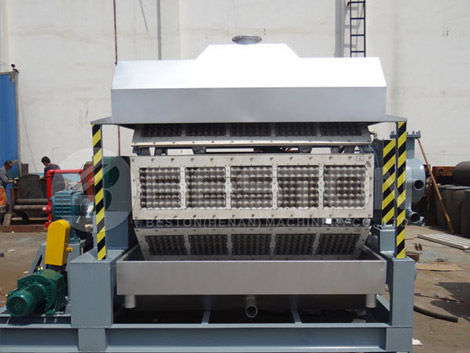

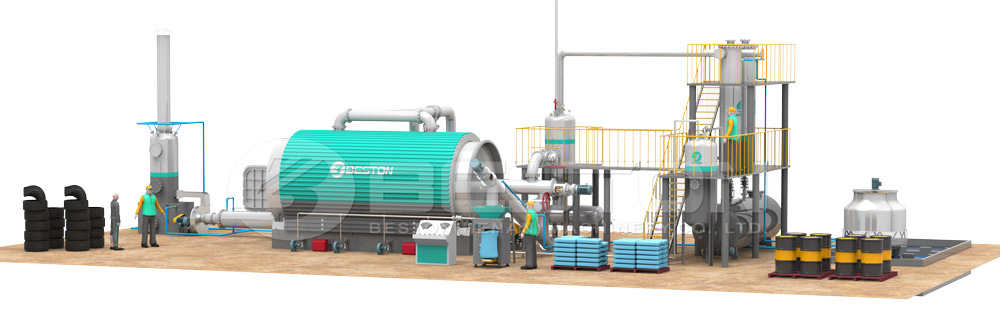

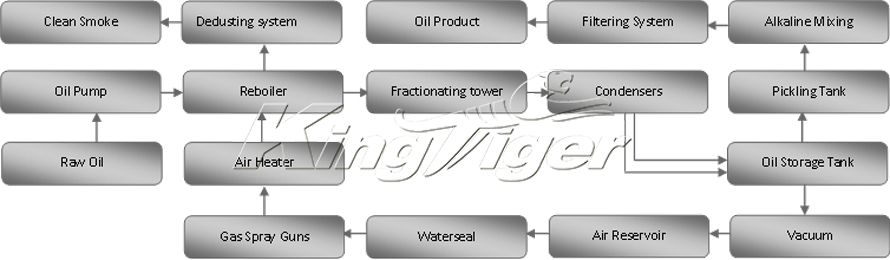

Automating the process of creating egg trays is highly simplified when you are working with in pulp molding machines. They are designed to fit together easily, and the creation of the egg trays is not only fast but also easy to understand. It uses waste paper as raw material. These materials will be broken into pulp a pulping machine. Once this takes place, they are liquefied, and sent through a screening process. This will help remove any contaminants and colorations from their store. This may then be sent by way of a proportioning machine along with a concentration regulator. After that, this liquid will be poured into the egg tray machine itself. Then you will get wet trays, which will be heated, and subsequently sent into a conveyor belt where they will be stacked, labeled, and also the product will probably be packaged. If you want more details about how to make egg trays from waste paper, you can check the link here: https://bestoneggtraymachine.com/how-to-make-egg-trays-from-waste-paper/.

Where To Find The Lowest Prices

Low prices will originate from businesses that have been producing egg tray making machines for decades. They have perfected the process of making them, and can even save you money if you need one of the more advanced units. These machines are designed to create what could be thousands of trays per hour, and this may be exactly what you are looking for. You should verify that the company you are purchasing from is legitimate and has a good reputation with people before you make an offer. Beston Machinery is the one we recommended, in which you can get a paper egg tray manufacturing project report.

How To Find The Location Of These Companies Quickly

Finding the location of these businesses is as easy as looking for egg tray making machines online. These ads will lead to websites that will tell you about each business and provide you with their contact information. In the span of just a few days, you will have multiple quotes back from these reliable businesses that can sell you one or more of them. Choose from the semiautomated to the fully automatic egg tray making machines that are offered at the lowest prices. As you sift through the different listings, make sure that you see feedback from others that have made a purchase from this business. This is the only way you can verify that they are religion of the company.

Egg Tray Machines in Dominica

If saving money is important to you, and you need find the best paper egg tray machine, these suggestions will make this process easy. If you need one that can produce thousands of egg trays per hour, you should know that there are multiple businesses that can sell you a machine that can do this without fail. India is always growing, and part of that growth involves providing food for the masses. If you have a farm that produces many eggs, you will certainly need one of these machines that can produce egg trays automatically.